62cruiserinc

Petty Officer 1st Class

- Joined

- Oct 30, 2009

- Messages

- 295

Re: Floor replacement question

Since I had chosen not to remove the cap, I was going to splice the stringers just under the front bow section.

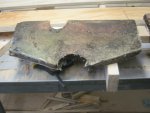

On the left side stringer, there was a large cutout for the fuel filler hose near the area where I was going to splice. I did not feel a splice here would have been very strong, so i removed the whole stringer by crawling under the bow section with a HF multi-tool. Here is a picture of the stringer removed with the cutout section:

As you can see most of the stringer was cut out, leaving less than an inch of stringer width in the narrowest section. The factory added a 3/8" thick piece of plywood as a gusset in this area. I am going to add an extra 1/2 layer of arauco ply in this area. The outer side of the stringer at the bow end is an area where the hull goes sharply vertical, and it appears that the factory poured in a bunch of resin and fibers to fill the area. There is a "glass wall" up against the side of the stringer for the last 8" of stringer. I think I am going to put PB against this side of the stringer to glue it to the existing glass since it is not possible to access this area after the stringer is in place. I will tab the inside edge as usual.

The other stringer is in perfect shape for the part under the bow section:

This is where the splice is going to go. I plan on using a 3/4" plywood gusset that will be screwed to the old and new stringers and also have a layer of PB on the contact surfaces for extra holding power.

I did notice one other thing when removing the stringers. Both stringers had areas where the bottom 3/8" or so was black or rotted. Since this area would not have bben accessible to core sampling, there was no way to tell that there was rot here. Apparently water had gotten into the slot formed by the stringer tabbing and travelled down the slot. I am glad that I decided to remove the stringers and replace them.

Steve

Since I had chosen not to remove the cap, I was going to splice the stringers just under the front bow section.

On the left side stringer, there was a large cutout for the fuel filler hose near the area where I was going to splice. I did not feel a splice here would have been very strong, so i removed the whole stringer by crawling under the bow section with a HF multi-tool. Here is a picture of the stringer removed with the cutout section:

As you can see most of the stringer was cut out, leaving less than an inch of stringer width in the narrowest section. The factory added a 3/8" thick piece of plywood as a gusset in this area. I am going to add an extra 1/2 layer of arauco ply in this area. The outer side of the stringer at the bow end is an area where the hull goes sharply vertical, and it appears that the factory poured in a bunch of resin and fibers to fill the area. There is a "glass wall" up against the side of the stringer for the last 8" of stringer. I think I am going to put PB against this side of the stringer to glue it to the existing glass since it is not possible to access this area after the stringer is in place. I will tab the inside edge as usual.

The other stringer is in perfect shape for the part under the bow section:

This is where the splice is going to go. I plan on using a 3/4" plywood gusset that will be screwed to the old and new stringers and also have a layer of PB on the contact surfaces for extra holding power.

I did notice one other thing when removing the stringers. Both stringers had areas where the bottom 3/8" or so was black or rotted. Since this area would not have bben accessible to core sampling, there was no way to tell that there was rot here. Apparently water had gotten into the slot formed by the stringer tabbing and travelled down the slot. I am glad that I decided to remove the stringers and replace them.

Steve