nola mike

Vice Admiral

- Joined

- Apr 22, 2009

- Messages

- 5,786

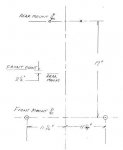

I'm replacing my 3.7L with a 4.3. Next week's project is going to be to glass in some new motor mounts. I've had some advice on how to measure, what to do, etc, but couldn't find a ton of info. I replaced the floor a few years back, and the stringers are in good shape back there.

1. I don't plan on cutting into the existing fiberglass or stringers, if possible.

2. Looks like the best course of action would be to laminate 1/2" or 3/4" exterior ply (needs to be from lowes if I'm going to get it done). Do I use PB in between or glue?

3. Ideas for matting?

4. Any gotchas? I'm scared of building it up too high. If I err on the low side by 1/2" or 3/4, will a shim suffice?

1. I don't plan on cutting into the existing fiberglass or stringers, if possible.

2. Looks like the best course of action would be to laminate 1/2" or 3/4" exterior ply (needs to be from lowes if I'm going to get it done). Do I use PB in between or glue?

3. Ideas for matting?

4. Any gotchas? I'm scared of building it up too high. If I err on the low side by 1/2" or 3/4, will a shim suffice?