MikeDobbs

Petty Officer 1st Class

- Joined

- May 8, 2015

- Messages

- 205

Hey everyone-

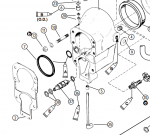

I'm working on reinstalling my leg after a bellows job and I can't quite figure out all the gaskets. Seems like there are o-rings that don't apply, and some possibly missing?

There are 3 o-rings on the drive shaft- are these supposed to be in this kit? The new ones don't look the right size... Also, there's a large thick circular ring that I figured would go over the cylinder where the shaft is (that fits into the bell-housing), but it's not a tight fit and keeps slipping off. Is this a gen one ring that I don't need?

Thanks in advance for the help... kit looks something like this:

I'm working on reinstalling my leg after a bellows job and I can't quite figure out all the gaskets. Seems like there are o-rings that don't apply, and some possibly missing?

There are 3 o-rings on the drive shaft- are these supposed to be in this kit? The new ones don't look the right size... Also, there's a large thick circular ring that I figured would go over the cylinder where the shaft is (that fits into the bell-housing), but it's not a tight fit and keeps slipping off. Is this a gen one ring that I don't need?

Thanks in advance for the help... kit looks something like this: