Yesterday

Petty Officer 1st Class

- Joined

- Feb 21, 2012

- Messages

- 354

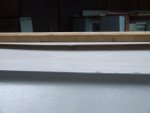

I have an old Chrysler tri hull I've been rebuilding for a number of years. I had it on the water for two seasons when I discovered something nasty. Because it sat for years with the transom hanging over the bunks of the trailer and had a large O/B motor installed. The transom sagged by about 3/4" and I not knowing better, assumed the shape was they way the boat was made. On top of that, I had to replace the keel, and it looks like the bottom of hull on one side was uneven when everything was rebuilt, leaving the rear part of one half of the hull, lower than the other by about an inch!

I thought about using filler it but 1" is a bit extreme, so here is a potential plan:

The boat is upside down so I can work on the hull. I thought I might cut the hull at its lowest point on that half from the side to the keel (about 4" ahead of the stern) and lift up on the hull in the hooked are pulling it out. I would then use expanding closed cell urethane foam to fill in the gap, and once it's set up, I could repair the cut I've made.

Does this plan sound reasonable? If not any suggestions? If yes, any helpful tips? I hate the idea of cutting the hull but Im not sure I have any better alternative choices.

I thought about using filler it but 1" is a bit extreme, so here is a potential plan:

The boat is upside down so I can work on the hull. I thought I might cut the hull at its lowest point on that half from the side to the keel (about 4" ahead of the stern) and lift up on the hull in the hooked are pulling it out. I would then use expanding closed cell urethane foam to fill in the gap, and once it's set up, I could repair the cut I've made.

Does this plan sound reasonable? If not any suggestions? If yes, any helpful tips? I hate the idea of cutting the hull but Im not sure I have any better alternative choices.