September Update . . .

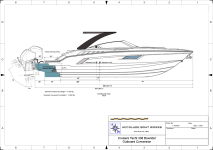

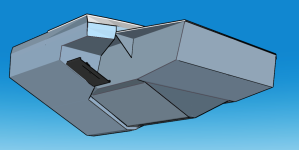

Boating season (for us) has come to a close, and over the past few months I have been firming up plans for the outboard conversion. My 3D modeling software has come in handy in finalizing the design.

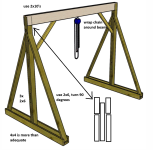

I plan on making a gantry for the heavy lifting . . . the rear seat assembly has to come off in order to pull the engines. . . probably weighs 400 lbs. Then I can use the gantry to pull the engines.

.

.

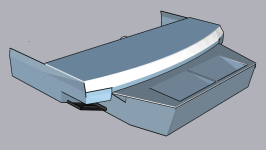

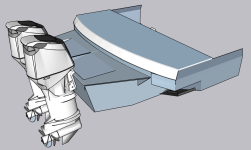

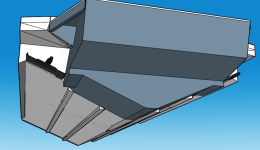

I am going with an outboard bracket that will also serve as a hull extension, what I am calling an 'extendo-bracket'

.

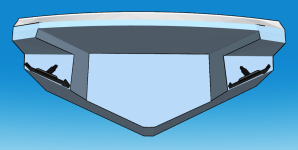

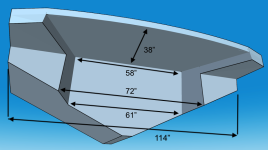

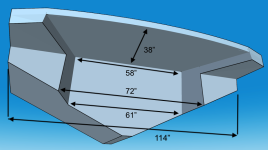

In designing the bracket, I wanted to take the shape of the boat's transom into consideration.

.

.

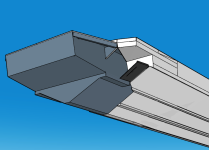

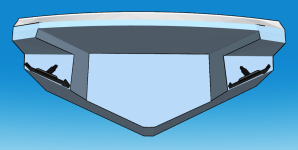

The 'flat' part of the transom is inset quite far and covers only about half of the boat's beam.

.

.

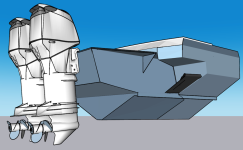

If I went with a traditional bracket, it would be only about 58" wide. Certainly wide enough for the twin engines, but probably falling short on the hull extension/planing surface criteria. So, I decided to go with the 72" width as a compromise, not messing with the trim tab areas.

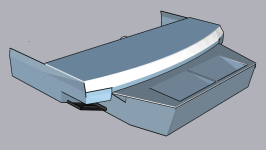

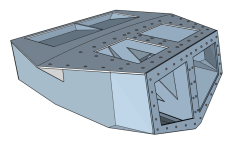

Another consideration was fiberglass vs. aluminum. If I go with aluminum, I would probably want to have a space between the top of the bracket and the underside of the swim deck (corrosion prevention consideration). This would mean that the bracket would need to 'hang' off the transom. Considering the proposed length of the bracket ( 65") . . . that seems like a lot of cantilever.

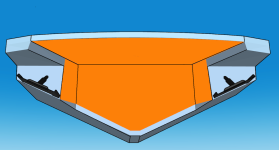

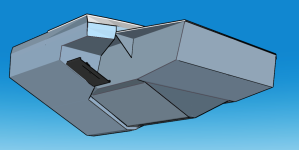

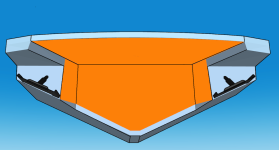

If I go with fiberglass, (probably Coosa-cored fiberglass construction) I can more readily attach the bracket to the underside of the swim deck, making it be more like a hull extension. The contact areas of the extendo-bracket will be something like this . . . (shown in orange)

.

.

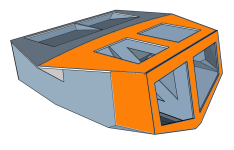

The extendo-bracket will have the mating contact areas as illustrated below. . .

.

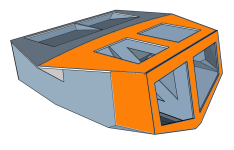

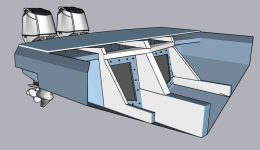

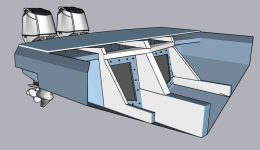

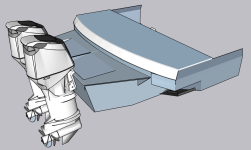

The installed extendo-bracket will look something like this . . .

.

I am planning on a 2" step of the hull extension portion and its planing surface length will be about 40".

.

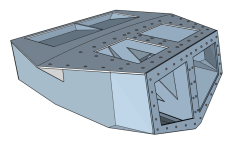

There will be adhesive and lots of fasteners holding the extendo-bracket to the boat.

.

Probably about 80 fasteners (SS bolts) in total. My technical assessment is that 'it's not moving' . . .

Cruisers Yacht sent me pictures and drawings of the OB version of their boats a while back, so I could see how they add bracing to the transom area in support of the bracket. I plan on doing something similar with an added 'cross bar' at the top of the transom. (The bracing is shown in white, added to the top of the existing stringers).

.

.

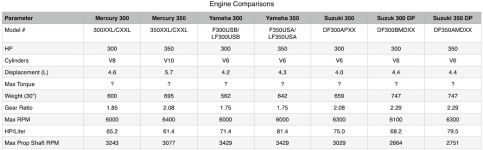

As for the engines, I am thinking 300 HP for the twins . . .

.

.

Speaking of engines: I've got some quote requests out and have a first set of #'s back . . . A bit more than I had estimated, but not terribly so. The quote I have is all the top-shelf stuff, more than what I was looking for, so there should be some wiggle room. Basically the controls and rigging are more than the cost of an engine

. . . .

Anyway, I'll post updates as things get rolling . . . the boat will be coming out of the water in the next week or so, then the conversion will be 'Job 1' for the next few months.