RoGun_Mako171

Petty Officer 3rd Class

- Joined

- Jun 25, 2018

- Messages

- 79

After replacing the head gasket on the port side, I noticed cylinder 2 and 4 becoming very hot within 2 minutes or so while connected to muffs, while 1 and 3 were very cool to touch. I could keep my hand on the 2 or 4 cylinder for 5-7 seconds, so somewhere in the 130-140 degree range. Thinking I had a bad thermostat, I did a thermostat service and no corrosion (engine is only used in non-salt water) and both thermostats operate the same, so I put it back together, swapping the thermostats and found the same results.

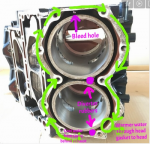

After doing some research, I decided to run it for a bit with the hoses from the heads to the thermostat housing disconnected and (thankfully) no more heating of the port side! Very happy to rule out water getting into the heads from my head gasket replacement. So now I'm thinking I must have a blockage somewhere, but I'm not sure where. Some additional info is that the port side idle relief does not spray water when running on muffs, but the starboard side does. And the drain hole on the port side of the lower unit does not have the same water pressure as the starboard side.

Any ideas where I should start looking for the blockage?

After doing some research, I decided to run it for a bit with the hoses from the heads to the thermostat housing disconnected and (thankfully) no more heating of the port side! Very happy to rule out water getting into the heads from my head gasket replacement. So now I'm thinking I must have a blockage somewhere, but I'm not sure where. Some additional info is that the port side idle relief does not spray water when running on muffs, but the starboard side does. And the drain hole on the port side of the lower unit does not have the same water pressure as the starboard side.

Any ideas where I should start looking for the blockage?