76SeaRay

Lieutenant Junior Grade

- Joined

- Aug 24, 2017

- Messages

- 1,071

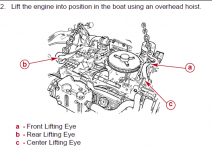

I have test fitted my engine twice. The first time with no exhaust manifolds and without the closed cooling system. For that I bolted chains into the bolt holes on the front and back of the heads on both sides The next time no exhaust manifolds and I had the closed cooling system on but pulled the heat exchanger back off (its heavy). There was no way to chain to the front of the engine and the normal lifting brackets won't fit anywhere with the closed cooling system installed so I used an intake manifold bracket (via carburetor studs) to lift the engine. I don't like that approach. Anyway, I am trying to figure out where I can put a thru hull sea water fitting in and locate where the Alpha trim/tilt pump, Boat Leveler pump, batteries, and ACR will fit. So, I need to drop the engine in again for fitting purposes.

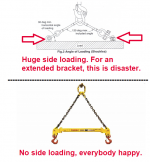

My problem is that I have the engine ready to test fire and break-in on the engine stand as soon as I finish wiring the engine harness. That means everything is on the engine and the closed cooling system including the block is filled with coolant water. I am guessing the weight to be around 1,000lbs. I have a gantry crane rated at 1 ton (Harbor Freight model) with two chain hoists (one 1 ton and one 2 ton). So, is there a way to use lifting straps around the engine, maybe thread them between the exhaust manifolds and heads as opposed to disassembly of the engine at this point? I can still bolt to the back of the heads but there is no place in the front of the engine for a bracket or chains. Suggestions?

My problem is that I have the engine ready to test fire and break-in on the engine stand as soon as I finish wiring the engine harness. That means everything is on the engine and the closed cooling system including the block is filled with coolant water. I am guessing the weight to be around 1,000lbs. I have a gantry crane rated at 1 ton (Harbor Freight model) with two chain hoists (one 1 ton and one 2 ton). So, is there a way to use lifting straps around the engine, maybe thread them between the exhaust manifolds and heads as opposed to disassembly of the engine at this point? I can still bolt to the back of the heads but there is no place in the front of the engine for a bracket or chains. Suggestions?