Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,932

Re: My first, ( Larsons Tri-Hull)

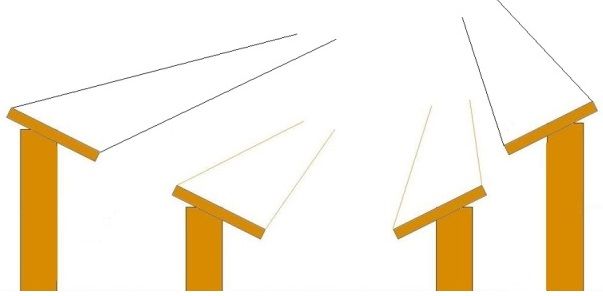

To cut your deck out set your circ saw to 3/4" and cut out a square in the middle. Check the thickness of the deck If it's 3/4" continue on and cut all around the perimeter of the hull. If it's 1/2" then adjust the depth of the cut. Cut several more slices in the hull and then use pry bars to get it all out. I wouldn't worry about trying to save it just get it out!!!! As already stated make SURE to measure everything at several points and take a lot of pics. Mark the sides of the hull right where the deck attaches so you'll have a reference point after the decks been removed. Wiring usually runs under the port side gunwale. Wiring a boat is really some basic stuff. Not much to it. When the time comes I can supply you with some diagrams. Your boat should run about a 70 to 85 hp motor. I really Like Johnson and Evinrudes. Keep up with the Clean Out and Demo. Don't worry about the cap removal yet. that'll come later. We do need to start thinking about getting the hull supported so it's either get the trailer built properly or make a cradle to sit her on.

To cut your deck out set your circ saw to 3/4" and cut out a square in the middle. Check the thickness of the deck If it's 3/4" continue on and cut all around the perimeter of the hull. If it's 1/2" then adjust the depth of the cut. Cut several more slices in the hull and then use pry bars to get it all out. I wouldn't worry about trying to save it just get it out!!!! As already stated make SURE to measure everything at several points and take a lot of pics. Mark the sides of the hull right where the deck attaches so you'll have a reference point after the decks been removed. Wiring usually runs under the port side gunwale. Wiring a boat is really some basic stuff. Not much to it. When the time comes I can supply you with some diagrams. Your boat should run about a 70 to 85 hp motor. I really Like Johnson and Evinrudes. Keep up with the Clean Out and Demo. Don't worry about the cap removal yet. that'll come later. We do need to start thinking about getting the hull supported so it's either get the trailer built properly or make a cradle to sit her on.