Olias

Petty Officer 3rd Class

- Joined

- May 28, 2013

- Messages

- 99

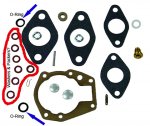

Still struggling with my 60' Evinrude 10hp Sportwin. Right now I'm about to do my 2nd carb rebuild just to be sure I didn't miss anything a few weeks ago on the 1st rebuild. In specific, I'm not positive I got the Needle washers and packing seated properly. !st off, am I crazy or are they the exact same thing? They are all red and the most abundant of all the parts in the kit. All the other parts, gaskets, O-Rings, etc., are pretty obvious so the 7 little red washers must be both the packing AND washers, right? See my pic below for reference. Secondly, is there a trick to getting them seated properly? According to the parts diagram both washers and packing (2 for each needle) go down into the threaded tubes BEFORE the needle(s). For me this was dang near impossible as they are pretty stiff and not soft and flexible like the O-Rings. Are they supposed to go ALL the way down in there before you insert the needle or do you cheat and twist them on the front of the needle 1st and then try to thread the needle in? Hope that makes sense. Thing is, it seems like with the washers/packing being way down at the front of the needle that the "packing nut/tube" that screws down over the top of the needle and supposedly butts up against the 2nd washer wouldn't even be close to the washer. Maybe I'm wrong and it all works out once everything is in and tightened down. Lastly, can you use a dab of Vaseline or grease on the washers to help coax em' down there or will the petroleum in those products eat away at the washers? Any advice would be greatly appreciated. Thanks.