Watermann

Starmada Splash of the Year 2014

- Joined

- Jan 12, 2013

- Messages

- 13,842

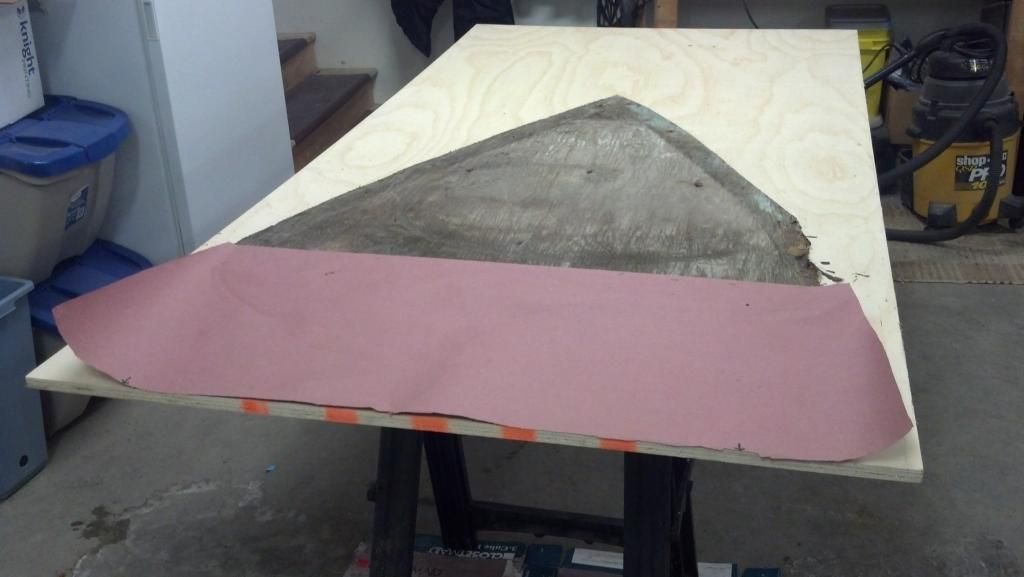

Nice to have templates and not mulch that's for sure. Yeah that old styrofoam is not good, even if it looks good now, how about in a few years, 10 years? Closed cell high density foam boards are the way to go.

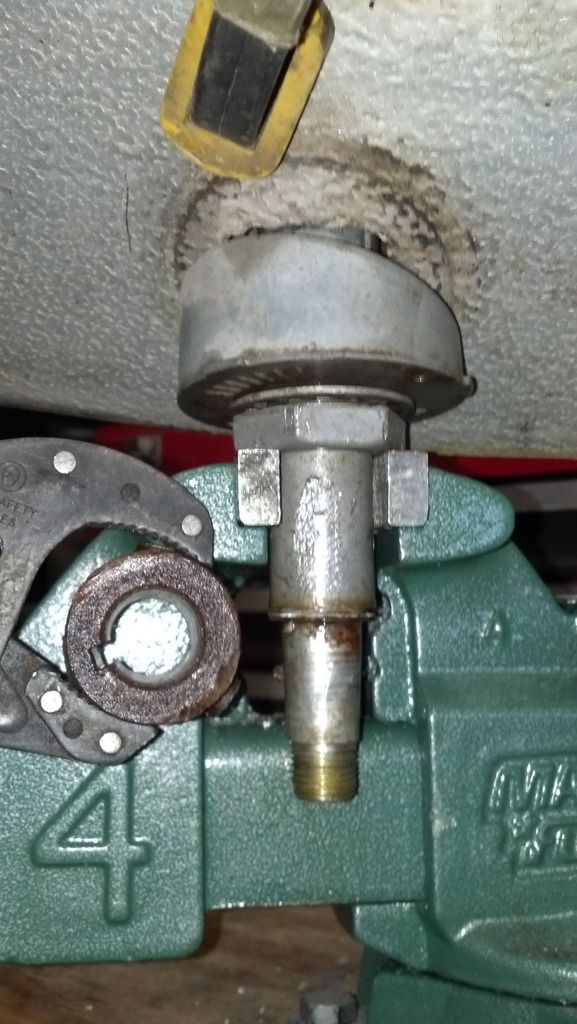

That wally dog looks tasty!

That wally dog looks tasty!