1959Cherokee

Seaman

- Joined

- Dec 27, 2011

- Messages

- 64

Hello everyone, Danny from North Texas here.

I have been a long time lurker around this site and felt it time to introduce myself.

Let me start by saying I am impressed with the wealth of collective knowledge on this forum.

I have read through many of the FAQ's and top secret files and they have got me out of more than one bind.

So onto the boat!!

She is a 1959 15' Cherokee Aluminum V-Hull with a 1990 Evinrude 25.

I bought her from the maintenance guy at my apartment complex for 600 dollars.

The motor is in good condition, starts easily and has 105 psi compression on both cylinders.

The trailer is also good to go.

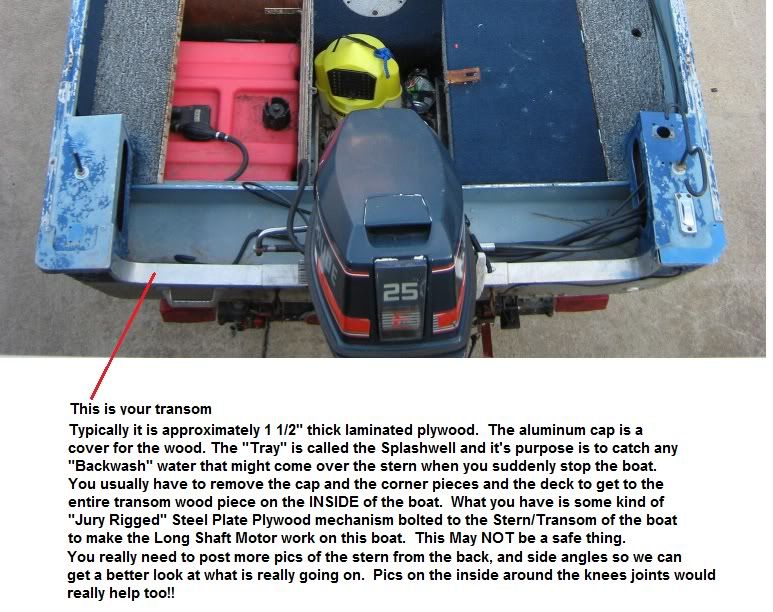

The boat's paint, interior and transom are not so good to go.

I should mention at least at this point I do not mean to restore this boat to immaculate condition.

I am fully aware of how I get with projects and sometimes things do get out of hand but would just like to make her into a capable, reliable and functional fishing boat.

That being said the exterior will certainly need some work.

I have read the FAQ regarding painting aluminum boats and once the interior work and transom is taken care of thats next.

Here are a few more pics.

*Note* I did not put the "32" on there lol. I think the previous owner got it from an auction and they did that.

I have just finished my first leg of the interior work last week.

I had meant to simply replace the front casting deck because it completely rotted through.

However, once I started pulling off the carpet I noticed every bit of the deck was rotten and it all had to go.

Here are some more pics of the interior before I started gutting.

I'll pick this up again in another post, apparently I can only attach 6 img files.

I have been a long time lurker around this site and felt it time to introduce myself.

Let me start by saying I am impressed with the wealth of collective knowledge on this forum.

I have read through many of the FAQ's and top secret files and they have got me out of more than one bind.

So onto the boat!!

She is a 1959 15' Cherokee Aluminum V-Hull with a 1990 Evinrude 25.

I bought her from the maintenance guy at my apartment complex for 600 dollars.

The motor is in good condition, starts easily and has 105 psi compression on both cylinders.

The trailer is also good to go.

The boat's paint, interior and transom are not so good to go.

I should mention at least at this point I do not mean to restore this boat to immaculate condition.

I am fully aware of how I get with projects and sometimes things do get out of hand but would just like to make her into a capable, reliable and functional fishing boat.

That being said the exterior will certainly need some work.

I have read the FAQ regarding painting aluminum boats and once the interior work and transom is taken care of thats next.

Here are a few more pics.

*Note* I did not put the "32" on there lol. I think the previous owner got it from an auction and they did that.

I have just finished my first leg of the interior work last week.

I had meant to simply replace the front casting deck because it completely rotted through.

However, once I started pulling off the carpet I noticed every bit of the deck was rotten and it all had to go.

Here are some more pics of the interior before I started gutting.

I'll pick this up again in another post, apparently I can only attach 6 img files.