1959Cherokee

Seaman

- Joined

- Dec 27, 2011

- Messages

- 64

Re: New User Introduction.

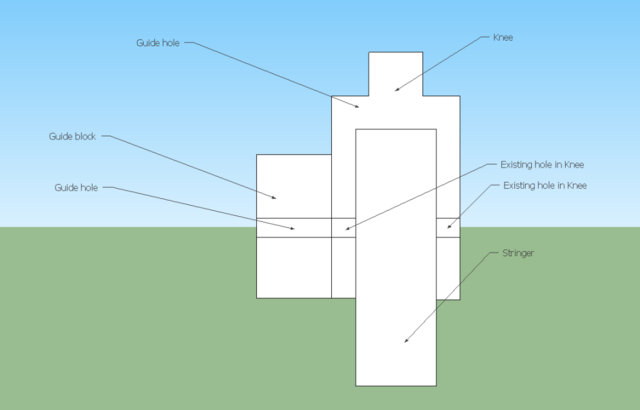

After everything was scraped and banged back into shape I started sanding with 220 grit and my handy mini mouse sander, while I wouldn't want to do an entire hull this way it worked very well for getting into the tight spots around the stringers and rivets at the base of the inner transom skin.

For the edges I couldn't even get the mouse in there so switched to a wire brush.

At this point I had spent about 2 hours sanding and scraping and the inner skin was feeling smooth!!

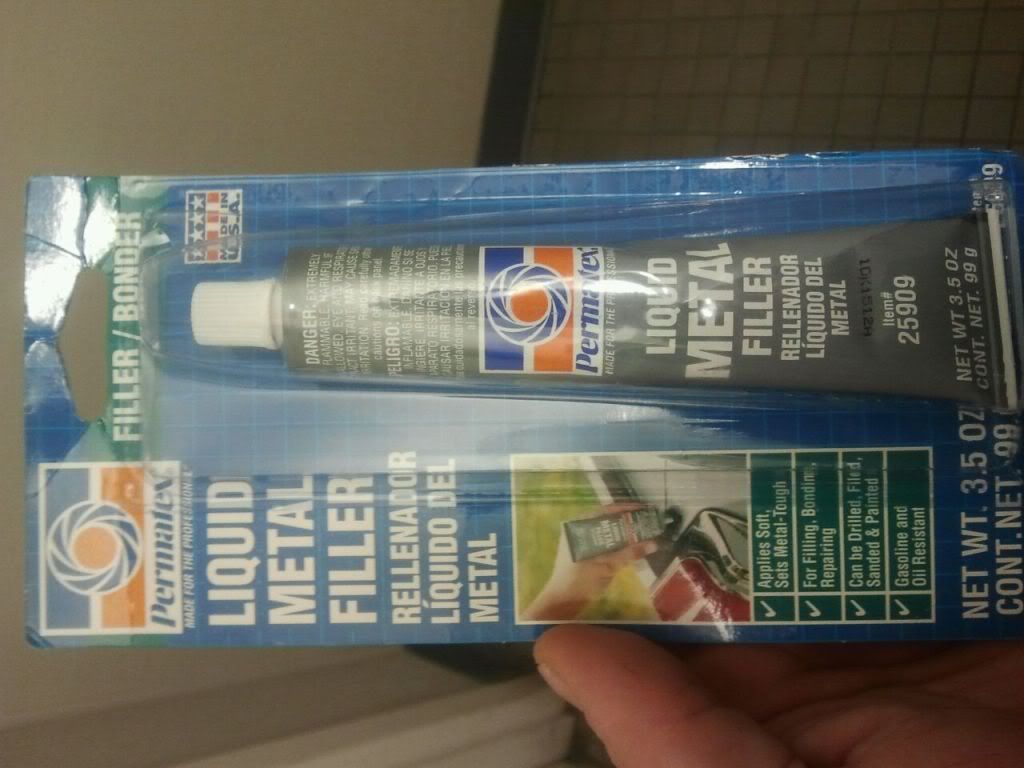

The other side would have gone just as easily but as mentioned earlier I ran into some moderate pitting that needed to be filled before any priming could be done.

After everything was scraped and banged back into shape I started sanding with 220 grit and my handy mini mouse sander, while I wouldn't want to do an entire hull this way it worked very well for getting into the tight spots around the stringers and rivets at the base of the inner transom skin.

For the edges I couldn't even get the mouse in there so switched to a wire brush.

At this point I had spent about 2 hours sanding and scraping and the inner skin was feeling smooth!!

The other side would have gone just as easily but as mentioned earlier I ran into some moderate pitting that needed to be filled before any priming could be done.