redfury

Commander

- Joined

- Jul 16, 2006

- Messages

- 2,659

Re: Ooo! Sparkly! Redfury's Grinding again!

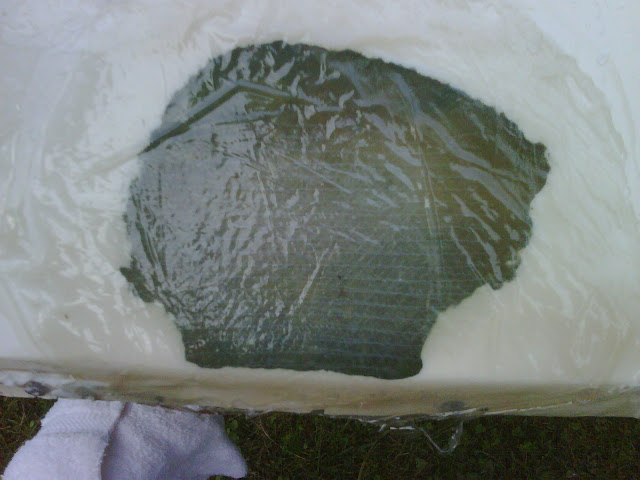

It's glass underneath the Gel coat everywhere I've ground out a blister. Along the sides of the strakes I was getting a tiny droplet of water out of some of them ( orange in color ). The glass that I did open up enough to see seemed to be resin starved.

Hell no! if it comes down to me grinding down the entire hull gel coat off, then that's what's going to happen...maybe. Or, I'll just take what I've got and make it as pretty as I can and worry about the paint job just a little less. It's not a show boat, and probably not my last boat.

BTW, I did a quick count of the areas I ground out yesterday...580. With today's grinding and the hard count from yesterday, I estimate that I'll have 2500 holes ground into the hull when it's all said and done.

Needless to say, I'm done for the day... the nerves in my hands are buzzing still after finishing grinding 20 minutes ago with the Dremel.

Unless suggested otherwise, I'm going to keep with the original plan and keep at it, then flood the voids with acetone or denatured alcohol with one of those squeeze bottle things ( gotta pick on up somewhere ), hit it with the hair dryer and see if I'm getting anything out of the holes.

Interestingly, some of the blister holes have turned glossy black in the centers.

I didn't know you were dealing with blisters.

Those blisters are due to the builder using putty to fill all of the difficult to roll areas, some builders will use it in a radius or a recessed area to help prevent air bubbles from being left in the laminate. Its a good idea, but frequently poorly executed, if they use the wrong putty, or use even the right one incorrectly, the bond between the gel coat and putty will be weak, resulting blisters.

The problem is that although you?ve ground out each blister and plan to fix each one, the entire bond line between the gel coat and putty is poor and these blisters are just the first places to visibly fail. As time goes on the entire area will become one big blister, although the spots you repair will hold up, but only those spots.

It's glass underneath the Gel coat everywhere I've ground out a blister. Along the sides of the strakes I was getting a tiny droplet of water out of some of them ( orange in color ). The glass that I did open up enough to see seemed to be resin starved.

Wow, That bites.

ondarvr,

Does that mean what I think it means? Should he grind the whole side area off.

RedFury,

I would hate to see you abort the boat after all the work you have already put in her.

Good luck

Bob

Hell no! if it comes down to me grinding down the entire hull gel coat off, then that's what's going to happen...maybe. Or, I'll just take what I've got and make it as pretty as I can and worry about the paint job just a little less. It's not a show boat, and probably not my last boat.

BTW, I did a quick count of the areas I ground out yesterday...580. With today's grinding and the hard count from yesterday, I estimate that I'll have 2500 holes ground into the hull when it's all said and done.

Needless to say, I'm done for the day... the nerves in my hands are buzzing still after finishing grinding 20 minutes ago with the Dremel.

Unless suggested otherwise, I'm going to keep with the original plan and keep at it, then flood the voids with acetone or denatured alcohol with one of those squeeze bottle things ( gotta pick on up somewhere ), hit it with the hair dryer and see if I'm getting anything out of the holes.

Interestingly, some of the blister holes have turned glossy black in the centers.