Re: Polyester Resin choices

ok....lets tool at this from a logical point of view first.

the tooling resin is for making molds.....so that is out.

700 ve resin is very good...it is stronger than poly and it is used in boat building lots....this is a viable choice....not as good as epoxy...but stronger than poly. it will cost more than standard resin by 1/3

435 standard layup resin....the cheapest solution that will work well in your boat. no issues.

b. 440....preimum.....dont really know about this resin......more than likely just a few additives that will give it a longer shelf life than the regular resin....will it be better for your boat?....i doubt it.

now......having said that.......what do the boat manufacturers use?.........the cheapest carp they can get..

...really..(in most cases).....

uasually there is a layer of good resin right next to the gellcoat but the rest is the lowest cost resin they can get.

we all forget here that fiberglass with cheap poly resin can be as strong as steel if used correctly. so even the worst decking resins are far stronger than the boat will need.

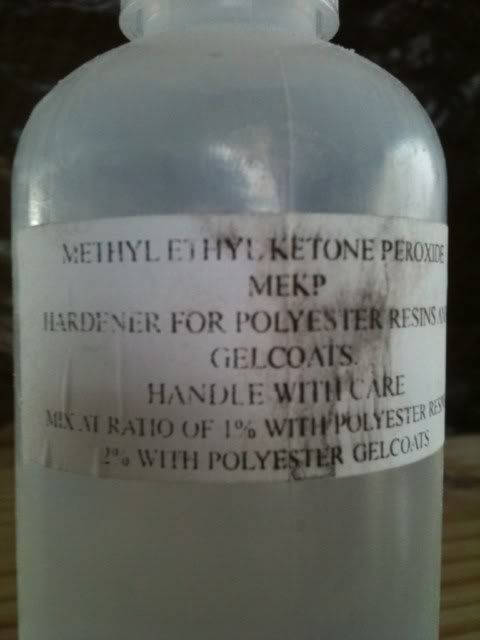

you still have to use the appropriate number of laminations for the required task, and follow the manufacturers specs on the proper mixing and catylisation rates......but in large....a standard cheap poly will be just fine.

just to further impress upon you the actual stregnth of the stuff........i mix up a special peanut butter (gype)....(oops super dooper peanut butter ver 5.2 ((pat pend))...lol

)

in a 1/4 inch sandwich......this stuff is so tough it cannot be broken by a 20 year old with a sledge hammer. ....i let some go off in a cup the guys took it out to the back alley and beat the heck outta that thing for about 20 mins with a sledge.......they hardly dented it......even the thinner areas stood up to the pounding.

so.....even cheap poly fiberglass resin is super strong !