Re: Project "1600 Capri Hard Top" has begun!

I don't think most cars use silicone for windshield glue. The last time I replaced a windshield I used a coil of tarry windshield adhesive... much stickier than silicone, also much nastier.

For a boat I'd recommend sikaflex.

Erik

Automotive windshields are held in place with two type of adhesives, first the glass is set on a strip of butyl rubber, then with a urethane adhesive which bonds the glass permanently. The butyl rubber bead provides the correct depth and spacing while the urethane glues the glass in. An automotive windshield is supposed to be able to retain the occupants in the event of a crash. Windshield urethane is black in color and just about non removable from unwanted surfaces.

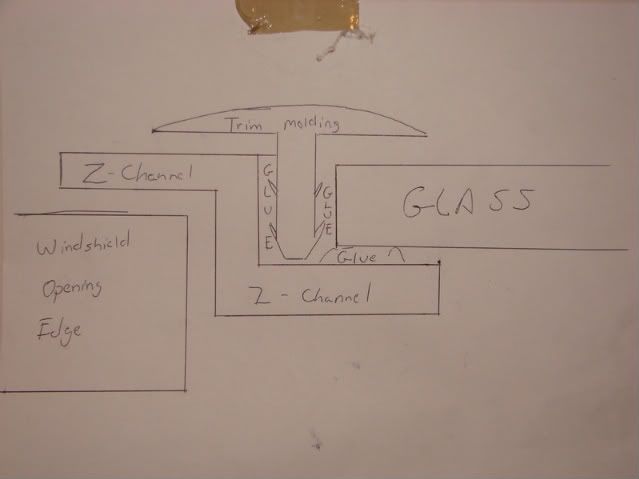

The problem with flat laminated glass is just that, being flat there is no structural rigidity. In a truck or bus, which is it's most common use, it's either framed in metal or secured on all sides with a rubber gasket. I think the easiest way to go about it would be to make an aluminum frame, maybe from a few old existing boat windshield frames and finding a way to secure that into a recessed fiberglass edge. Try going to a local glass shop, one that does motor homes, buses and trucks, they may have something that you could use. I'd say just form a lip and use a rubber gasket, but I think the process of seating the glass may be a bit tough on the fiberglass edge.

Take a look at how a window mounts in a camper cap, especially an older one, they use a flanged channel with a rubber insert to seal the glass to the channel. I usually just use sealing putty. The glass is framed on all sides, then screwed in place via a sandwich between an inner strip and the frame.

This would leave the glass well protected, fairly easy to repair if the need arises and it would leave a well finished edge. Many styles of frames can mount on a single flat edge as well.

Using an aluminum frame would eliminate the need for any glassed in window frame, the aluminum frame would form it's own supporting perimeter.

Any shop that sells camper caps or trailers should have spare parts and bulk aluminum edging. There's on near me that's been great for parts of all sorts.

I would probably make the frame and opening, then take the precut or partially assembled frame to the glass guy to cut a piece of glass to fit, unless you happen to be able to find an already correct fit camper window.

Try some of these sites for ideas:

http://www.glen-l.com/campers/suppliers.html#windows