- Joined

- Jul 18, 2011

- Messages

- 18,950

Greetings,

I have been wanting to add 3" riser extension blocks to my Mercruiser 7.4L engines exhaust, because the current setup is slightly below spec (1-2" low). Since I added an extended swim platform, the odds of sinking the stern lower with people is greater than before.

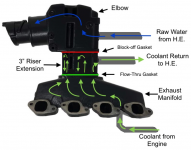

Anyway - the engines are full closed cooling - so coolant goes from the engine block out to the exhaust manifolds and back to the H.E. Currently, the setup is what you would call 'standard' with the elbows directly on top of the exhaust manifold - no riser block - and the block-off gasket is between the manifold and the elbow.

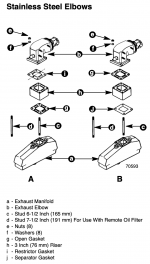

In my search for extension blocks, I have come across a few types in the 93320A part number series, which I assume is the right extension blocks for the manifolds (center rise type)

However, and my question is . . . there are 2 types of extension blocks that I have found . . .

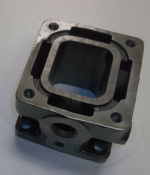

Straight riser blocks

.

Which would NOT be a good choice for the closed cooling setup - IMO.

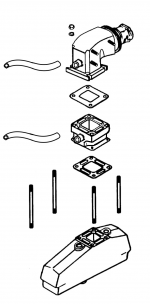

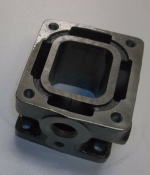

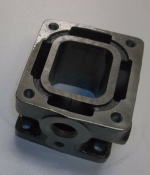

Then there are these . . .

.

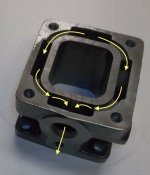

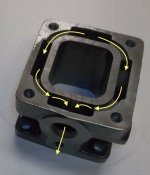

Which have small channels molded in between the 4 coolant ducts surrounding the exhaust duct. My thinking is that this will allow greater flow from around the extension block.

.

.

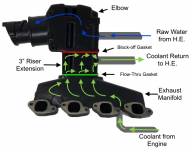

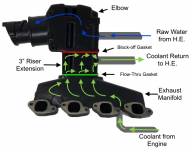

My plan for adding the extension block is diagrammed below . . .

I want the extension block to be part of the 'coolant' flow through the exhaust manifold, leaving just the elbow to have raw water (salt water in my case), as it is now.

I have seen part numbers of 93320A03, 93320A13 and a few other variants. The websites seem to use these numbers interchangeably, but my application would dictate a specific type.

My questions are:

1) Is my assumption correct that the extension block with the 'channels' are the correct ones for my application? or is there yet a third style of extension block to use with full closed cooling?

2) What would be the correct part number for the 2 styles of extension block? 'A03'or 'A13' ? or something else?

TIA for any guidance on this before I go buying parts . . .

I have been wanting to add 3" riser extension blocks to my Mercruiser 7.4L engines exhaust, because the current setup is slightly below spec (1-2" low). Since I added an extended swim platform, the odds of sinking the stern lower with people is greater than before.

Anyway - the engines are full closed cooling - so coolant goes from the engine block out to the exhaust manifolds and back to the H.E. Currently, the setup is what you would call 'standard' with the elbows directly on top of the exhaust manifold - no riser block - and the block-off gasket is between the manifold and the elbow.

In my search for extension blocks, I have come across a few types in the 93320A part number series, which I assume is the right extension blocks for the manifolds (center rise type)

However, and my question is . . . there are 2 types of extension blocks that I have found . . .

Straight riser blocks

.

Which would NOT be a good choice for the closed cooling setup - IMO.

Then there are these . . .

.

Which have small channels molded in between the 4 coolant ducts surrounding the exhaust duct. My thinking is that this will allow greater flow from around the extension block.

.

.

My plan for adding the extension block is diagrammed below . . .

I want the extension block to be part of the 'coolant' flow through the exhaust manifold, leaving just the elbow to have raw water (salt water in my case), as it is now.

I have seen part numbers of 93320A03, 93320A13 and a few other variants. The websites seem to use these numbers interchangeably, but my application would dictate a specific type.

My questions are:

1) Is my assumption correct that the extension block with the 'channels' are the correct ones for my application? or is there yet a third style of extension block to use with full closed cooling?

2) What would be the correct part number for the 2 styles of extension block? 'A03'or 'A13' ? or something else?

TIA for any guidance on this before I go buying parts . . .

Last edited: