Re: Well, I did it!

Re: Well, I did it!

I didn't make as much progress today as I was hoping... I had the day off of work because Im going on a trip to North Carolina on Wednesday. My plan was to spend the day on the boat and engine. Well, at 8 this morning I got was called in for a service call in Baltimore. Long story short, I didn't get to start on the boat until a little after two.

I decided with the little time I had, the floor was the biggest priority. I took a few pictures of what was in place now with trim and started ripping and tearing.

I pulled out all the carpet (Except for in the cabin) and started pulling up boards. Most of the screws either broke when I tried to remove them, or wouldn't budge. (Heads rusted to the point I couldn't get on them.) I used a crow bar and broke the heads off of those stubborn ones. The wood was very soft and offered little resistance. I also had to remove the fuel tanks to get to the screws underneath. These were riveted in place. I was unsure of the correct way to get them out, but I used a cold chisel and a hammer. (I was very careful about not creating any sparks. My chisel is coated in plastic on the striking end as well.) The rivets broke free and the tanks came right out.

Then I tore up the rest of the floor. I did not remove any foam yet, but it is just laying in the boat loose and is dry! I will pull it all out tomorrow (Don't have to work tomorrow either) and see how far I can go. I am going to take out the cuddy wall next, and see about the aluminum framework that supported the floor.

The two main beams in the center are solid except for where they meet the transom. The wood there is gone and the beams are just floating. The outer two beams are completely loose. It looks like they were riveted to the ribs of the hull at one point in time. The floor was replaced once before (I could tell by the number of holes from screws in the aluminum) and I guess they never fastened these outer beams?

My question today, is there any problems I will create by removing these support pieces? I need to get it to the point where I can fix any leaky rivets (there seem to be bunch at the front of the boat) and apply gluv-it. I need to haul the boat to work to perform most of this work. It's heated in there all winter, and they have a few over head cranes. They also gave me the ok to do this work because we won't have anything coming in for a while. I want to flip the boat but am a little concerned with damaging the hull if I remove this structure. Hopefully I am just parinoid, as it seems plenty strong.

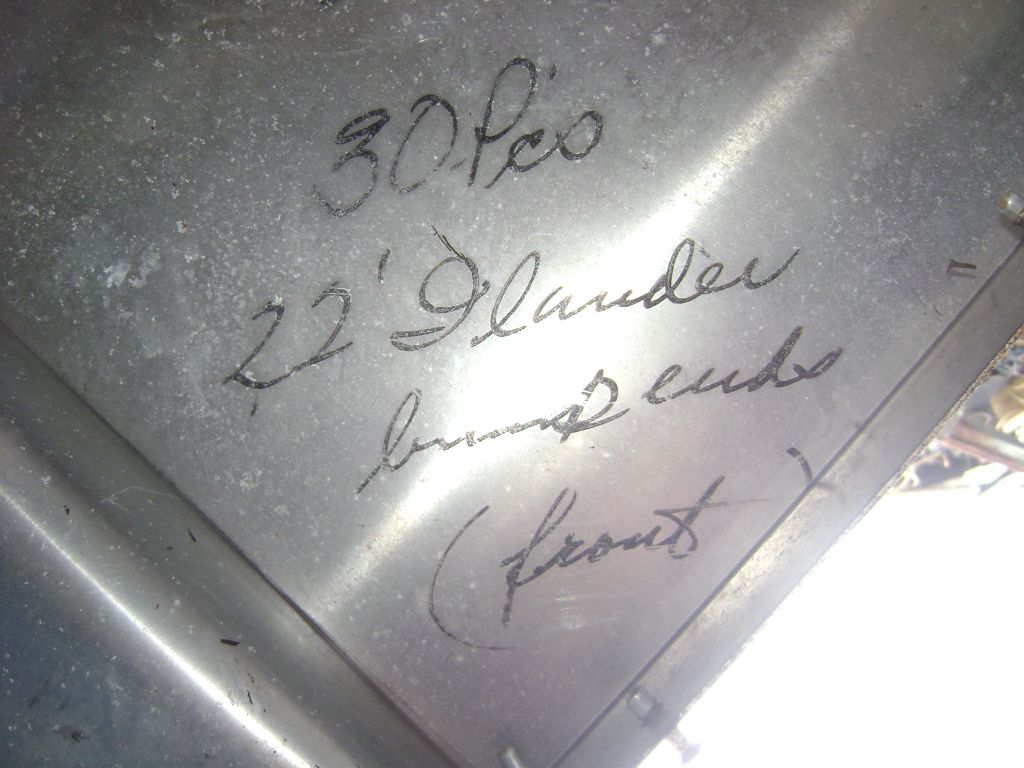

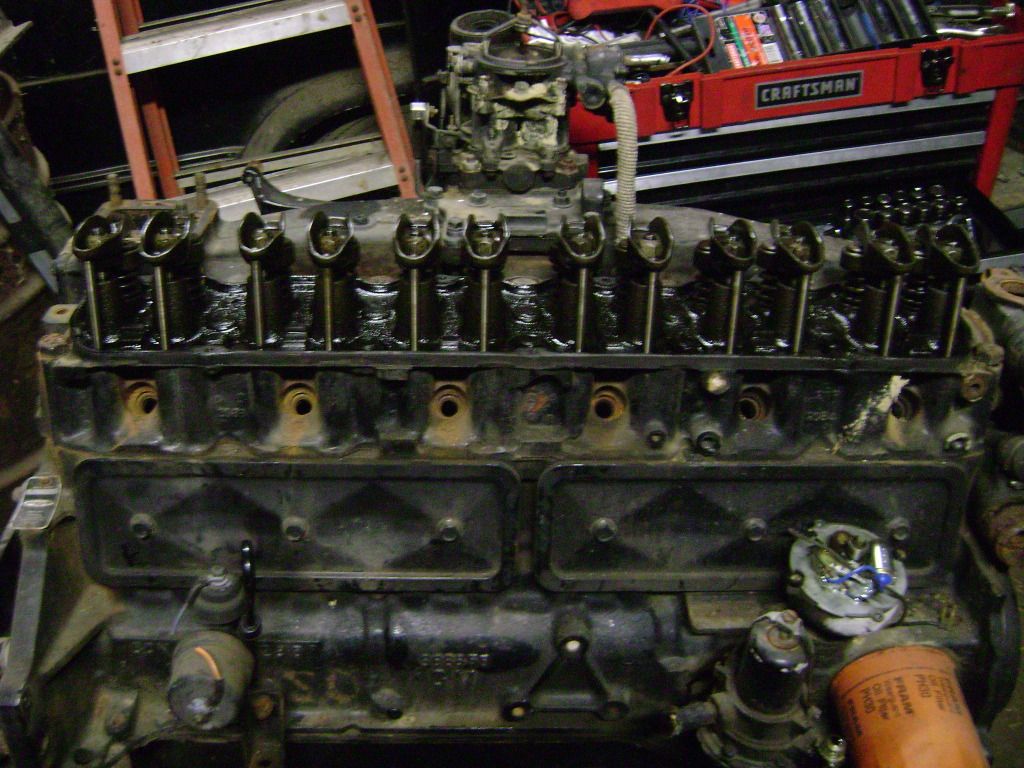

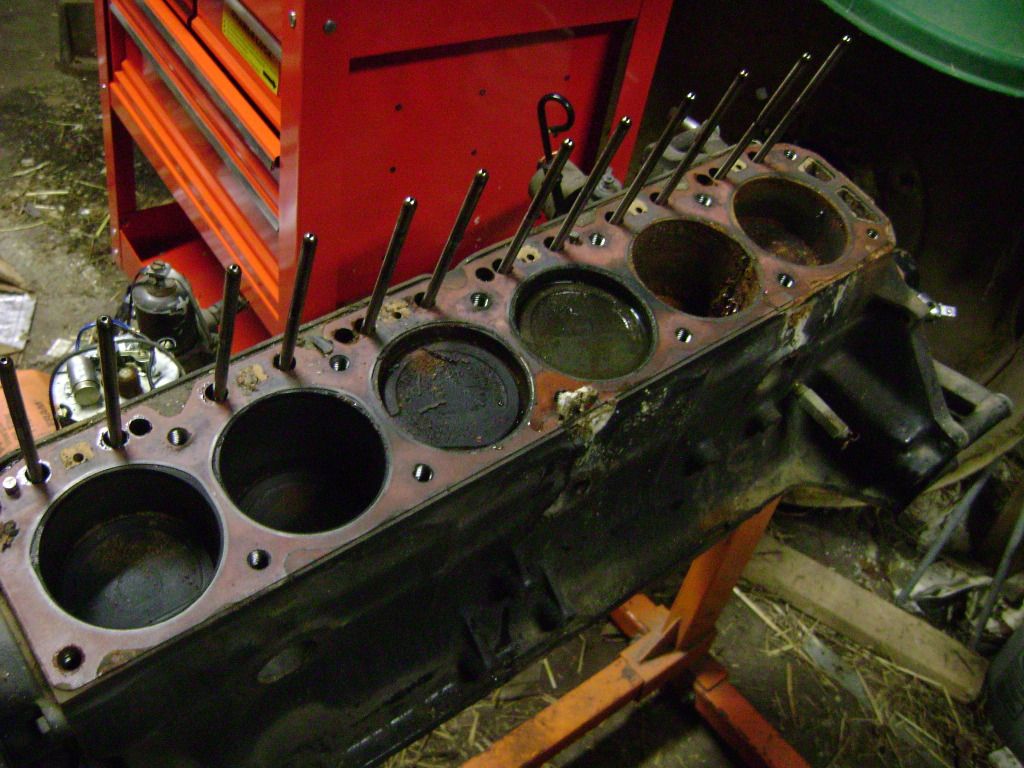

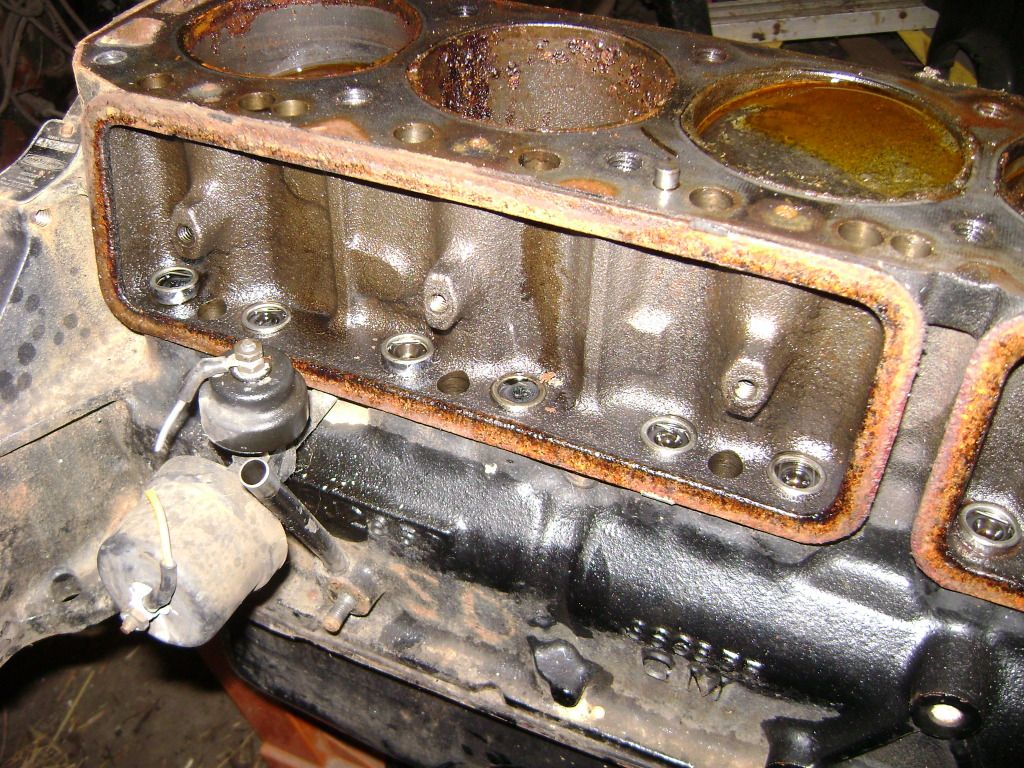

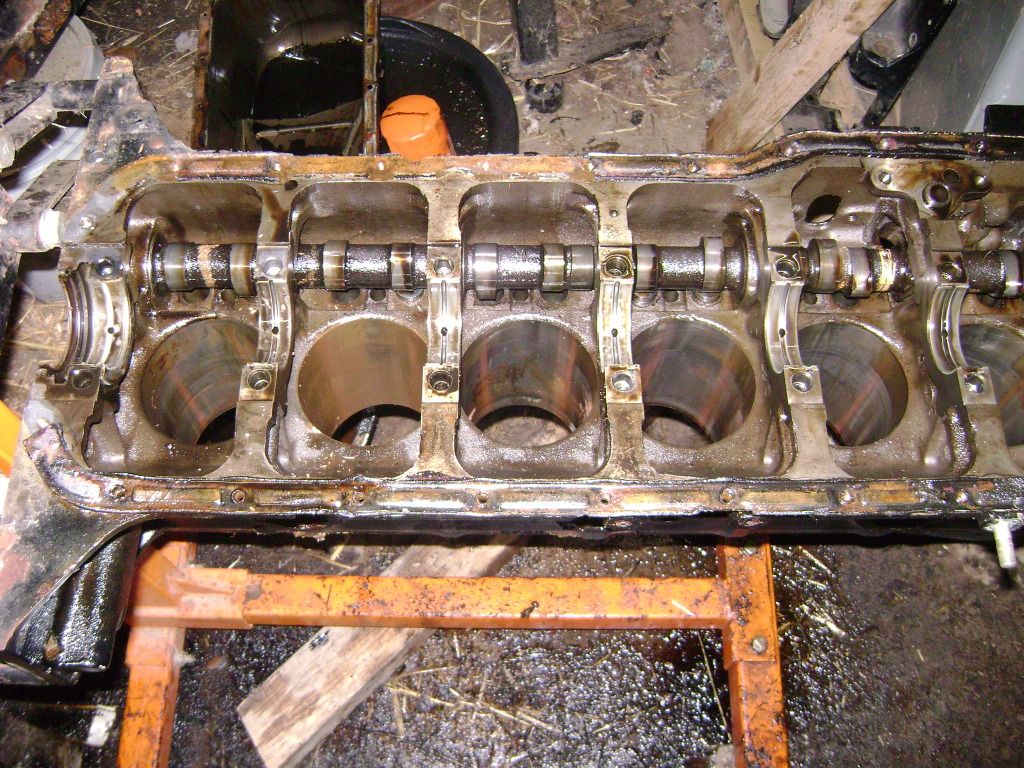

Also tomorrow, I am going to work on the engine. She seems pretty tight to me, but I am planning a complete rebuild anyhow. If it wants to be a real pain, I have an automotive chevy 250 sitting on the floor right now that I will put in. It only has 35000 miles on it and ran like a top when the vehicle was scrapped.

Once I see what is going on with the engine, I need to see about ordering parts. Except for the valves, valve springs and cam are there any internal differences between this marine engine and an automotive? I don't want to do this job again for a LONG time! haha.

I thank you for your time!

Foster