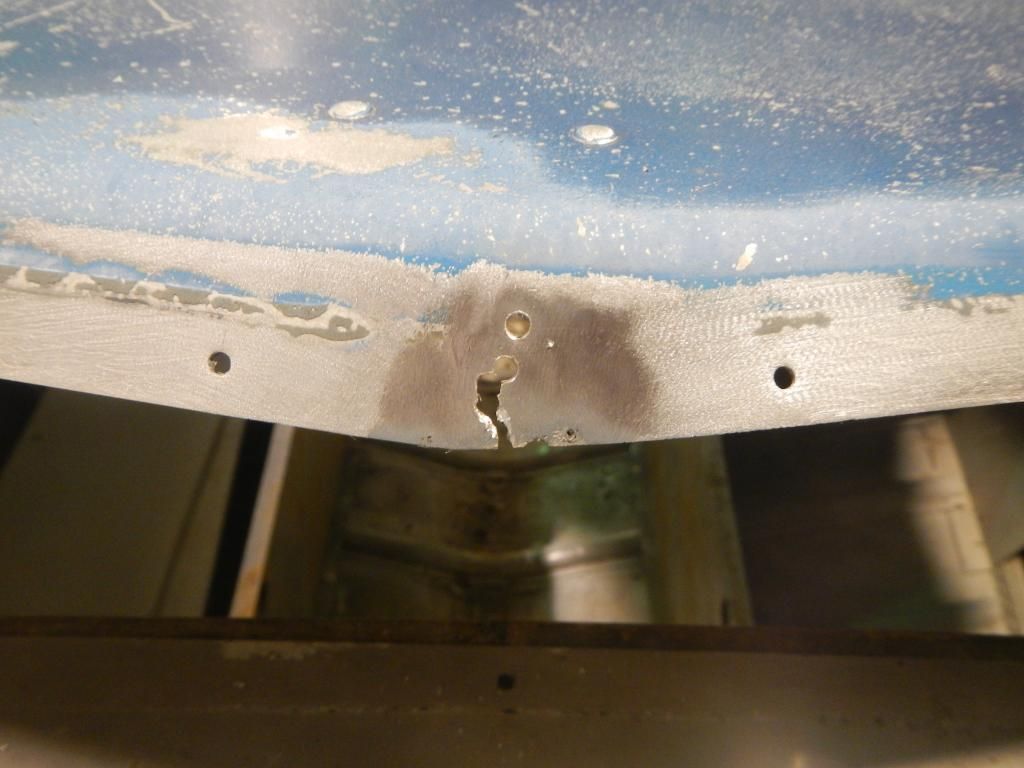

Looks like it's been a while... I have been making some progress! I wound up getting a fine grit flap disk on the angle grinder and did a nice job on the epoxy. Then I spoiled myself and got a $19 HF dual action orbital sander and got it all sanded. I should have bought that a while ago, the vibratory palm job just doesn't compare. I put two coats of Macropoxy down and am final sanding the second coat tonight. Tomorrow or Wednesday at the latest I will be spraying the first coat of blue. I can't wait!

I did see some other threads where Macropoxy/Acrolon was brought up and nobody seemed to have a concrete answer, and a reference was made to this thread. I will share what I found with this paint.

First off, Its very tough paint. Bumps and brushes don't have any effect on it what so ever. I did have a rough time trying to paint it, but that was using gravity fed hvlp guns. Since then, I bought a binks 2100 and a CA technologies 1 qt pressure pot and that has made all the difference. I still thin both, right at 10% and don't have any problems. If your not spraying, I wouldn't thin it and not worry. This stuff really is great so far! We use it exclusively on our equipment at work and even on old machines they still look great and the paint holds up well.

I will have pictures in the next few days, I am scheduled to leave for work again soon so I am going to try and get the paint finished before I leave.