Re: Starmada Testing Laboratories

B,

A quick search using google on plywood brings up all kinds of stuff.

And all I'm saying is the Douglas Fir is a better product from a hot, wet/dry cycling standpoint.

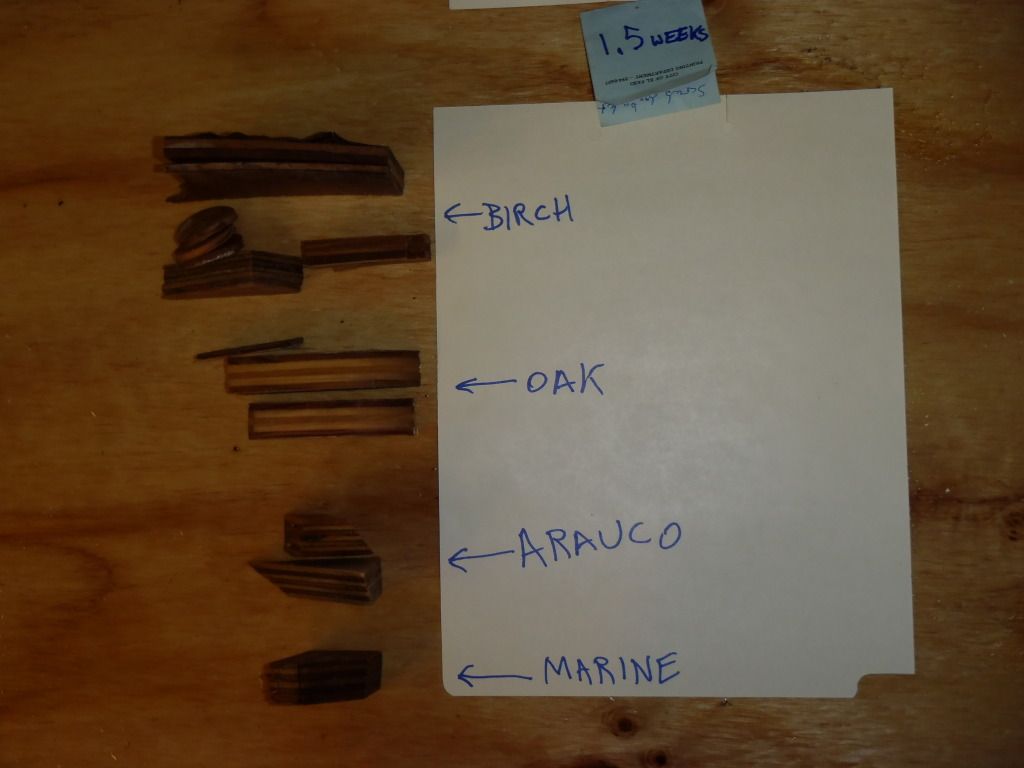

The thing I don't understand is going on a brand new guy's thread who comes here looking for help and seeing comments like "most of us here just use arauco or exterior grade plywood and it works just fine." I didn't use those products. E used exterior and had a bad experience with it drinking large amounts of resin. There are several others on iboats who feel the same.

If you do some research, some of the sites that talk about plywood exclude even douglas fir from being labeled marine grade since it is considered a soft wood. They say the plies must be made of okuume or meranti. Here's a quote

Marine plywood is manufactured from durable face and core veneers, with few defects so it

performs longer in humid and wet conditions and resists delaminating and fungal attack. Its construction is such that it can be used in environments where it is exposed to moisture for long periods. Each wood veneer will be from durable tropical hardwoods, have negligible core gap, limiting the chance of trapping water in the plywood and hence providing a solid and stable glue bond. It uses an exterior Water and Boil Proof (WBP) glue similar to most exterior plywoods.

Marine plywood can be graded as being compliant with BS 1088, which is a British Standard for marine plywood. There are few international standards for grading marine plywood and most of the standards are voluntary. Some marine plywood has a Lloyd's of London stamp that certifies it to be BS 1088 compliant. Some plywood is also labeled based on the wood used to manufacture it. Examples of this are Okoume or Meranti

Marine plywood is frequently used in the construction of docks and boats. It is much more expensive than standard plywood: the cost for a typical 4-foot by 8-foot 1/2-inch thick board is roughly $75 to $100 US or around $2.5 per square foot, which is about three times as expensive as standard plywood.

So you see the Douglas Fir Marine grade I used is really at the bottom of the pile as marine grades go but some of the stuff folks are using on their decks is not going to hold up very long and I feel like we should be letting folks know the risks associated with saving a few dollars.

I used 5 sheets of plywood on my deck at an upcharge of 250 bucks to use the Douglas Fir marine vs exterior and probably saved 50 bucks or so on resin so I feel that the additional cost was well worth it. And the upcharge cost to do a 16 footer would be what? less than 100 bucks?

Please don't think I'm flaming you here. I think a little bit of healthy argument is good. That's why some of us drive Fords and for some unknown reason, others drive Chevys

I just think we should be checking or opinions a little more when we're offering up our expertise....