Re: testing solenoid and where to get replacement

Well, it has been quite a while since I replied to this thread, but I have actually tried several things since then to try to solve this problem, but unfortunately I still have the same problem. :faint2:

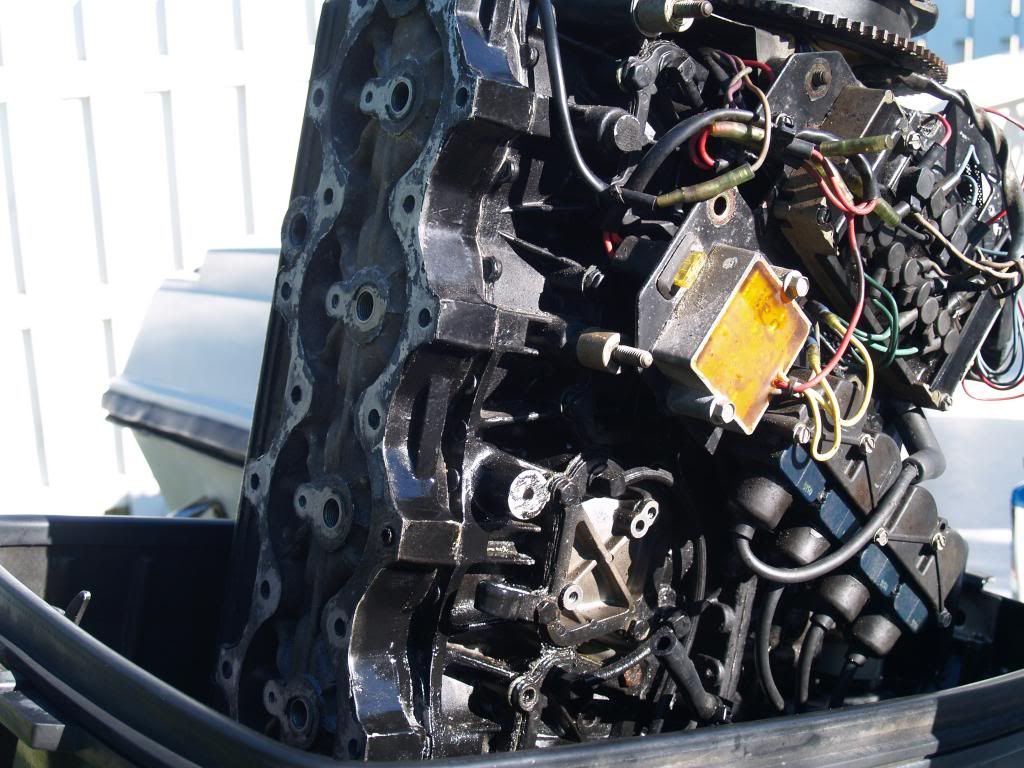

I did order the mercury starter rebuild kit and I carefully replaced all the brushes and put everything back together. I did notice the new springs were much "springier" than the old ones. But when i tried to start again I just had the exact same symptoms - starter will turn slowly for a second or two but that is all. So I just figured the starter was bad (it did have a lot of burnt smell when I took it apart) so I ordered a new one. So then the new one came in and I installed it and still had exact same symptom. I am not too upset about having a second starter since I figure now both of them are probably fine and it was only $79 for a new one online to have as a backup. So anyway even though I thought I had ruled out the solenoid being the problem since I had wired the battery before straight to the starter, I went ahead and ordered a new solenoid since it was only $22 online and I still could not get it started. But today I put in the new solenoid and have same exact issue.

I had pretty much ruled out the battery since I the problem began because the battery is only a few months old but I took it into where I bought it and had them test it tonight on two different machines and both machines said my battery was good. The only thing kind of suspicious about the battery is they said it was "overcharged". It is rated for 550 CA and it tested at 803 CA. I do keep the battery on a battery maintainer / trickle charger. Is it possible the trickle charger has malfunctioned and overcharged the battery and would that keep it from starting?

The only other thing I can think of are the battery cables. But I have examined them and they do seem okay - no noticeable cracks or anything. Is there a procedure for testing battery cables?

When I began with this problem I was determined not to just throw new parts at it and I have attempted to troubleshoot, but at this point I am running out of things to replace anyway. :lol:

Well, it has been quite a while since I replied to this thread, but I have actually tried several things since then to try to solve this problem, but unfortunately I still have the same problem. :faint2:

I did order the mercury starter rebuild kit and I carefully replaced all the brushes and put everything back together. I did notice the new springs were much "springier" than the old ones. But when i tried to start again I just had the exact same symptoms - starter will turn slowly for a second or two but that is all. So I just figured the starter was bad (it did have a lot of burnt smell when I took it apart) so I ordered a new one. So then the new one came in and I installed it and still had exact same symptom. I am not too upset about having a second starter since I figure now both of them are probably fine and it was only $79 for a new one online to have as a backup. So anyway even though I thought I had ruled out the solenoid being the problem since I had wired the battery before straight to the starter, I went ahead and ordered a new solenoid since it was only $22 online and I still could not get it started. But today I put in the new solenoid and have same exact issue.

I had pretty much ruled out the battery since I the problem began because the battery is only a few months old but I took it into where I bought it and had them test it tonight on two different machines and both machines said my battery was good. The only thing kind of suspicious about the battery is they said it was "overcharged". It is rated for 550 CA and it tested at 803 CA. I do keep the battery on a battery maintainer / trickle charger. Is it possible the trickle charger has malfunctioned and overcharged the battery and would that keep it from starting?

The only other thing I can think of are the battery cables. But I have examined them and they do seem okay - no noticeable cracks or anything. Is there a procedure for testing battery cables?

When I began with this problem I was determined not to just throw new parts at it and I have attempted to troubleshoot, but at this point I am running out of things to replace anyway. :lol: