Re: The 2010 FrankenMerc Project

It's time to rebuild some carbs. These are WH-40 Carbs off a 1989 XR4 as near as I can tell.

The main jets are .074 and the idles are .048 but there are no vent jets. With the smaller mains I suspect someone removed the vent jets not understanding their purpose and the motor leaned out on the top end. That's guess work not fact. I'll order up a set and put them back in.

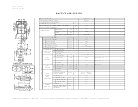

The first thing I do is take a Plano tackle tray and number it. When I pull the parts out I put them in a tray and write down a description with the tray number.

Next, I clean the carbs in paint thinner to get the surface gunk off then I take a bunch of pictures and store them on my computer and on PhotoBucket.com. This gives me a backup and lets me display them on this board.

The first pic I take is off the carb model number. This is not the serial number. The number 40 indicates the model and the first letter after the dash indicates the positon. This is top carb so it's number starts with -1.

Talk about beef, these are some throaty buggers, I'll bet their thirsty too!.

Now I dissassemble them. I always take the jets out first because it's easier to hold on to the carb. Then I take off the linkage, butterfly's and rod. Finally I remove all the fittings.

DO NOT TRY TO REMOVE THE SMALL FITTING ON TOP OF THE CARBS THESE ARE PRESSED IN AND NLA. These small fittings are for the enrichner circuit and can easily be cleaned without removing them.

When everthing is off the carbs I remove the bowl.

Finally I remove the float, needle and seats.

Once I have them all apart I wash them in paint thinner one more time then blow them out and put them into the carb cleaner. I use Gunk carb cleaner in the gallon can. I have for years and it's served me well.

Next I take all the parts that I have carefully separated and cataloged and put them all in the parts bucket and drop them into the carb cleaner.

Now if you think that sounds silly that I sorted them all out then mixed them all up you should think twice. Jets don't necessarily have to be the same size for each side of the carb and I've found parts that look identical but are not. If I separate and catalog them and later find out I didn't need to that's o.k. but if I didn't and they were different I'd have problems later down the road that would be hard to diagnose. I'll go through the same routine with #2 and #3.

Also notice that I do one carb at a time rather than tearing all of them down at once. This way when I put the first one back together I can use #2 as a reference. I also don't want to mix anything up between the carbs. They're marked 1,2,3 and it's for a reason so don't mix parts.