45Auto

Commander

- Joined

- May 31, 2002

- Messages

- 2,842

Re: thoughts on remanufactured engines

It would appear that you've never been in a rebuild OR factory engine.

If you define "perfect" as within specs, you are correct. But so is the $1500 rebuild.

Exactly what dimension on a lifter do you imagine is measured to a ten thousandth? And why would it be?

Hopefully you really aren't that naive.

Every manufactured product is built to as wide a tolerance as possible given it's operating requirements. There's a range of acceptable dimensions. It's actually very simple to rebuild an engine to much better than factory tolerances.

Given that I can buy a BRAND NEW Goodwrench crate long block for $1800, exactly how much care do you imagine that the factory puts into them?

http://www.summitracing.com/parts/NAL-12568758

The big rebuilders use the EXACT same equipment as the factories, but the cost percentage of the $1500 rebuild devoted to "finish" machining (boring, align honing, etc) is much higher than on the factory engine. GM has to do ALL the machining (oil galleries, combustion chambers, freeze plugs, tapped holes, crank journals, etc) from the RAW castings, while all the rebuilder has to do is bring the finish machining back into tolerance.

Since you obviously have no idea what goes into a rebuild, here's some pics for you from Rapido Marine.

http://www.rapidomarine.com/

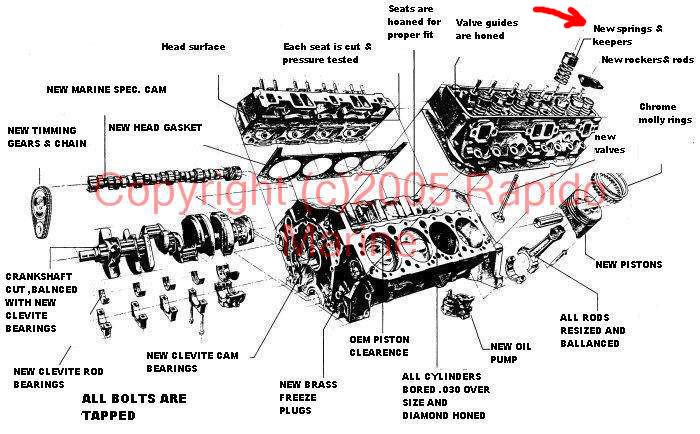

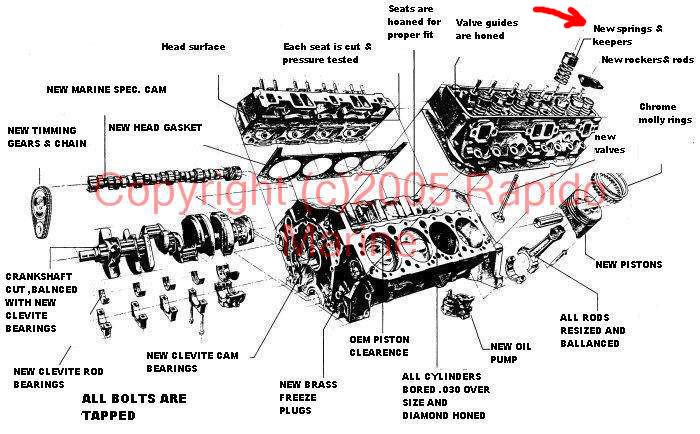

I even added a big red arrow to point out the new valve springs for you since that seemed to be a big concern of yours (maybe they bend the old ones so bad taking them off with your hammer that they have to use new ones!) - even though my 23 year old factory valve springs still deliver the same performance as when the boat was new.

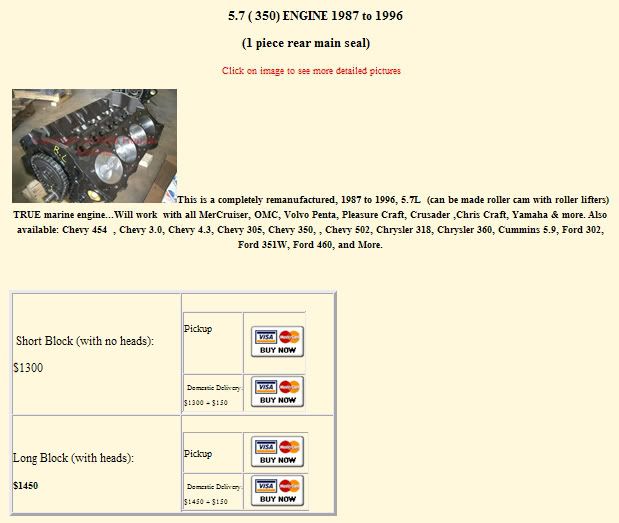

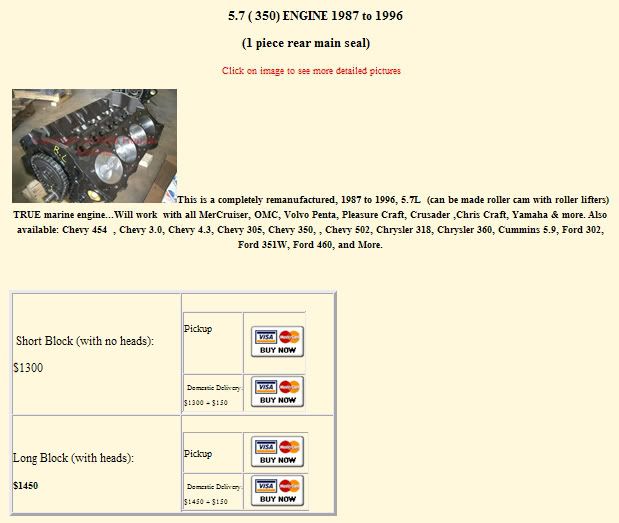

$1450 5.7L GM longblock:

Component view (look for the red arrow!):

Ever been in a $1500 rebuild?

It would appear that you've never been in a rebuild OR factory engine.

The factory clearances are usually perfect.

If you define "perfect" as within specs, you are correct. But so is the $1500 rebuild.

Lifters are mated in batches measured to the 0.0001th.

Exactly what dimension on a lifter do you imagine is measured to a ten thousandth? And why would it be?

Engine balance is perfect.

Hopefully you really aren't that naive.

Every manufactured product is built to as wide a tolerance as possible given it's operating requirements. There's a range of acceptable dimensions. It's actually very simple to rebuild an engine to much better than factory tolerances.

Given that I can buy a BRAND NEW Goodwrench crate long block for $1800, exactly how much care do you imagine that the factory puts into them?

http://www.summitracing.com/parts/NAL-12568758

The big rebuilders use the EXACT same equipment as the factories, but the cost percentage of the $1500 rebuild devoted to "finish" machining (boring, align honing, etc) is much higher than on the factory engine. GM has to do ALL the machining (oil galleries, combustion chambers, freeze plugs, tapped holes, crank journals, etc) from the RAW castings, while all the rebuilder has to do is bring the finish machining back into tolerance.

Since you obviously have no idea what goes into a rebuild, here's some pics for you from Rapido Marine.

http://www.rapidomarine.com/

I even added a big red arrow to point out the new valve springs for you since that seemed to be a big concern of yours (maybe they bend the old ones so bad taking them off with your hammer that they have to use new ones!) - even though my 23 year old factory valve springs still deliver the same performance as when the boat was new.

$1450 5.7L GM longblock:

Component view (look for the red arrow!):