Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,932

Re: Transom Help Needed - 1975 Tri hull

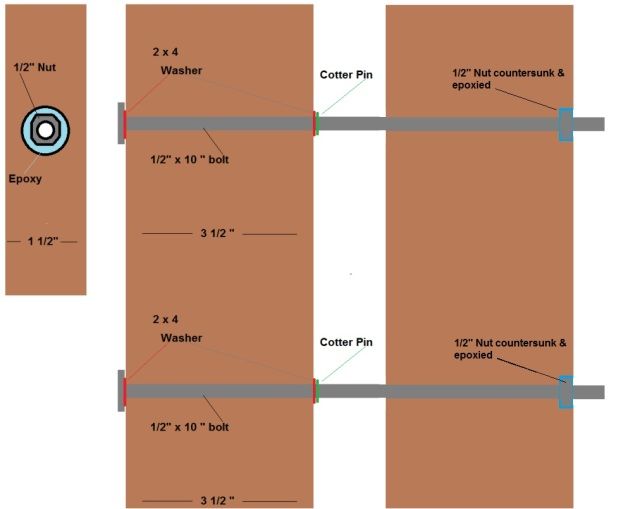

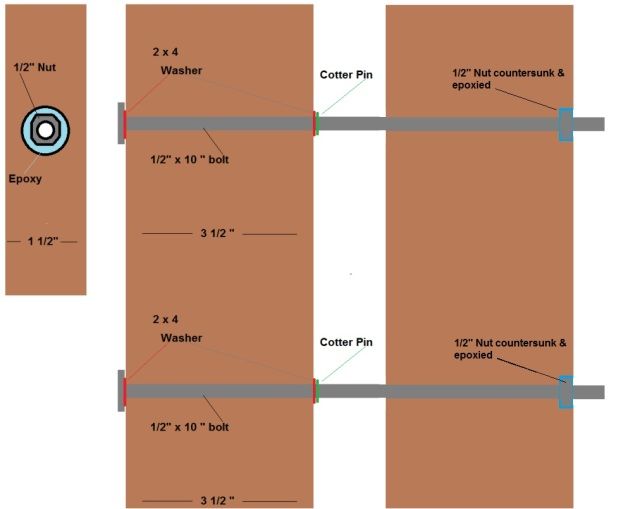

Ok, hopefully this pic will help a little better.

Washers and cotter pin on one board, a nut is countersunk and epoxied in the edge of the other board. To use the clamp you tighten the lower bolt until it is snug on the top of the transom then Loosen the top bolt to put pressure on the lower section of the transom. Once they are about equal then use equal amounts of turns to keep the pressure uniform. Practice makes perfect.

Ok, hopefully this pic will help a little better.

Washers and cotter pin on one board, a nut is countersunk and epoxied in the edge of the other board. To use the clamp you tighten the lower bolt until it is snug on the top of the transom then Loosen the top bolt to put pressure on the lower section of the transom. Once they are about equal then use equal amounts of turns to keep the pressure uniform. Practice makes perfect.