KnottyBuoyz

Senior Chief Petty Officer

- Joined

- Mar 6, 2006

- Messages

- 712

Thanks Scott. Great tip!

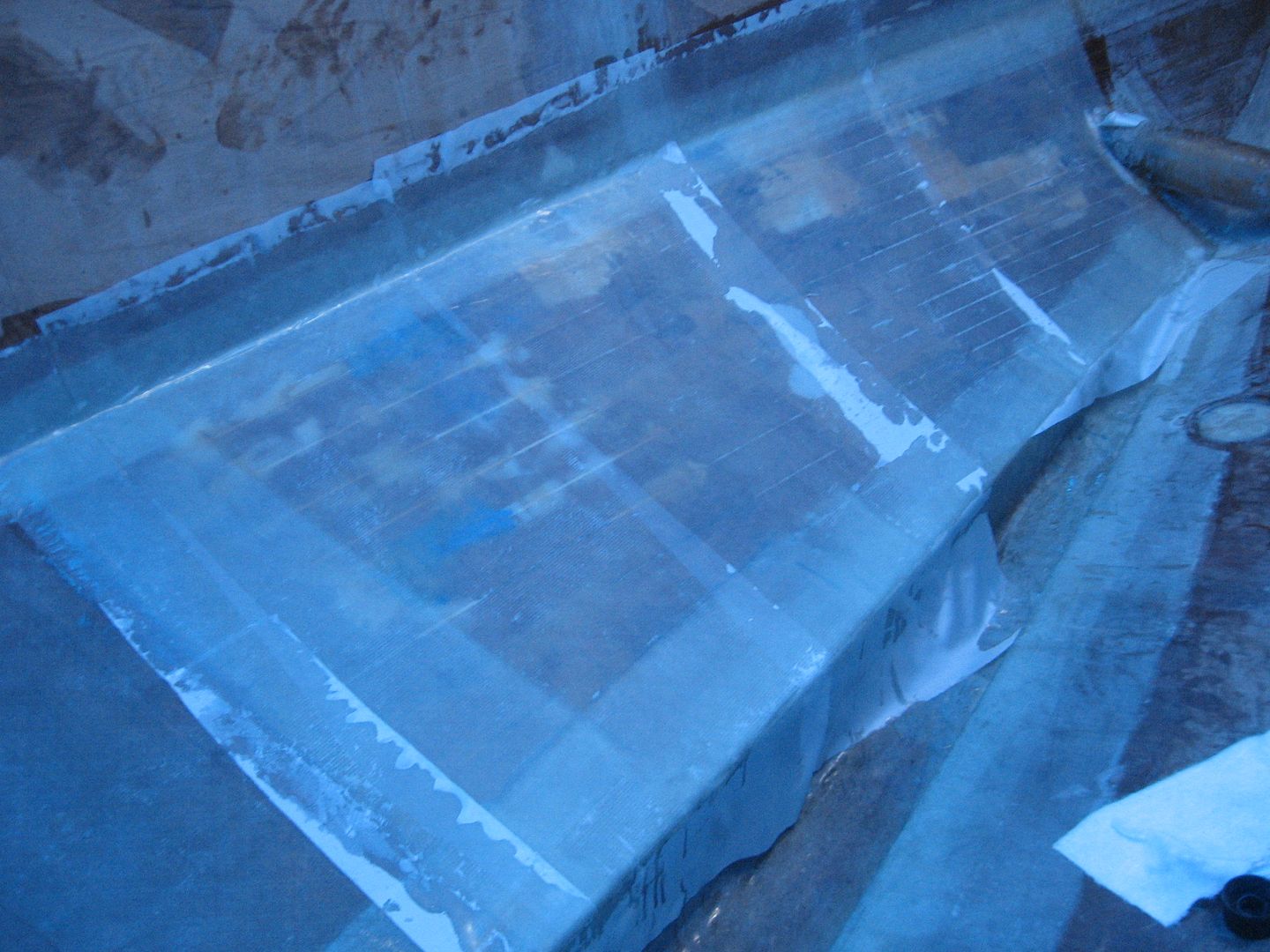

Bow section glassed in.

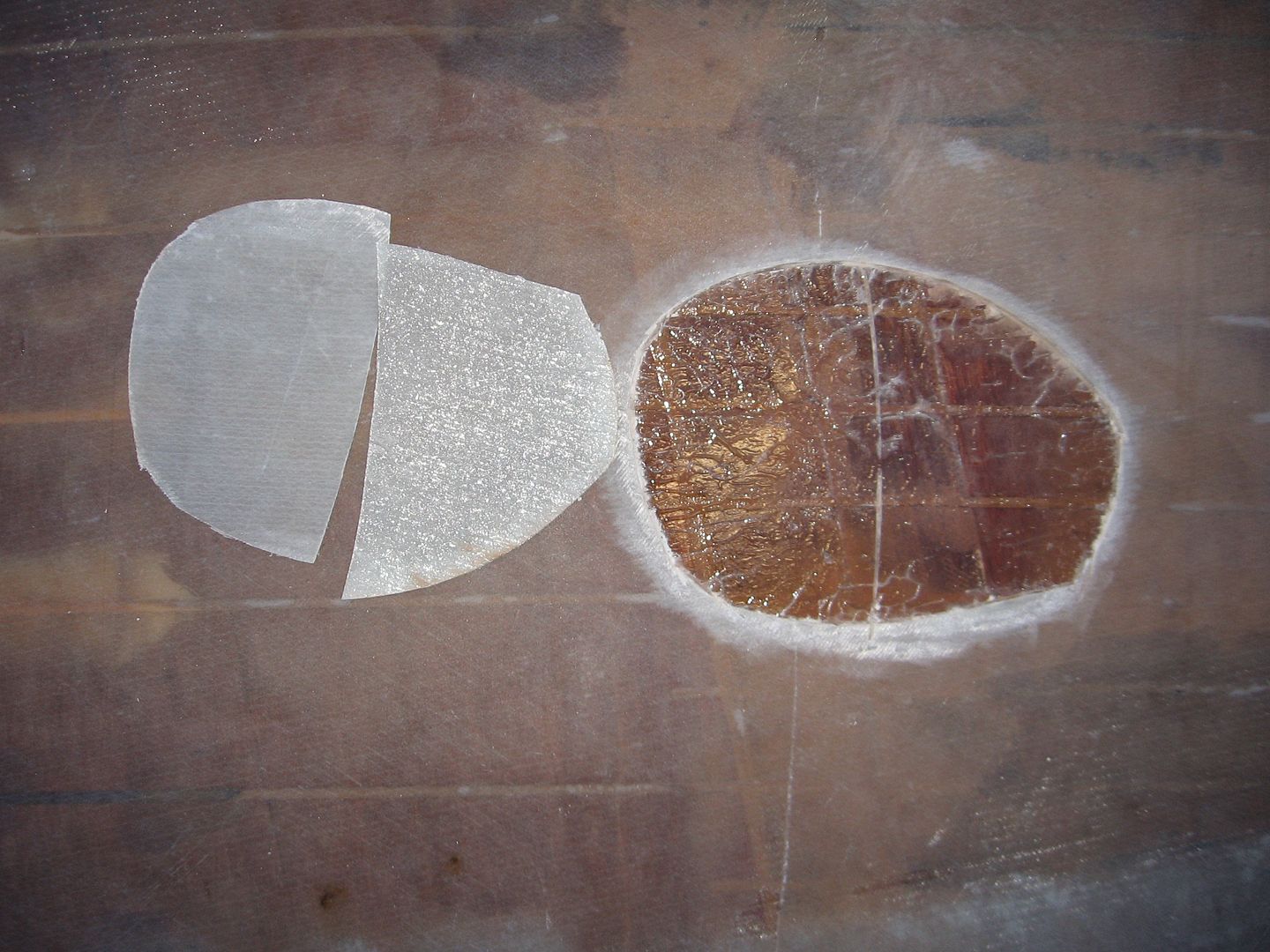

How many more times do I have to do this?[/URL]

What was on the hull in that section that was not allowing the cloth to stick?

I am guessing a few more times, or until you coat the inside with bilge paint just before dropping it in the water

Not absolutely sure. I'm guessing a drop of oil from my air powered sander maybe or the core got wet and was off-gassing moisture as the epoxy cured. Anyhow it's fixed now! Thanks for looking in.

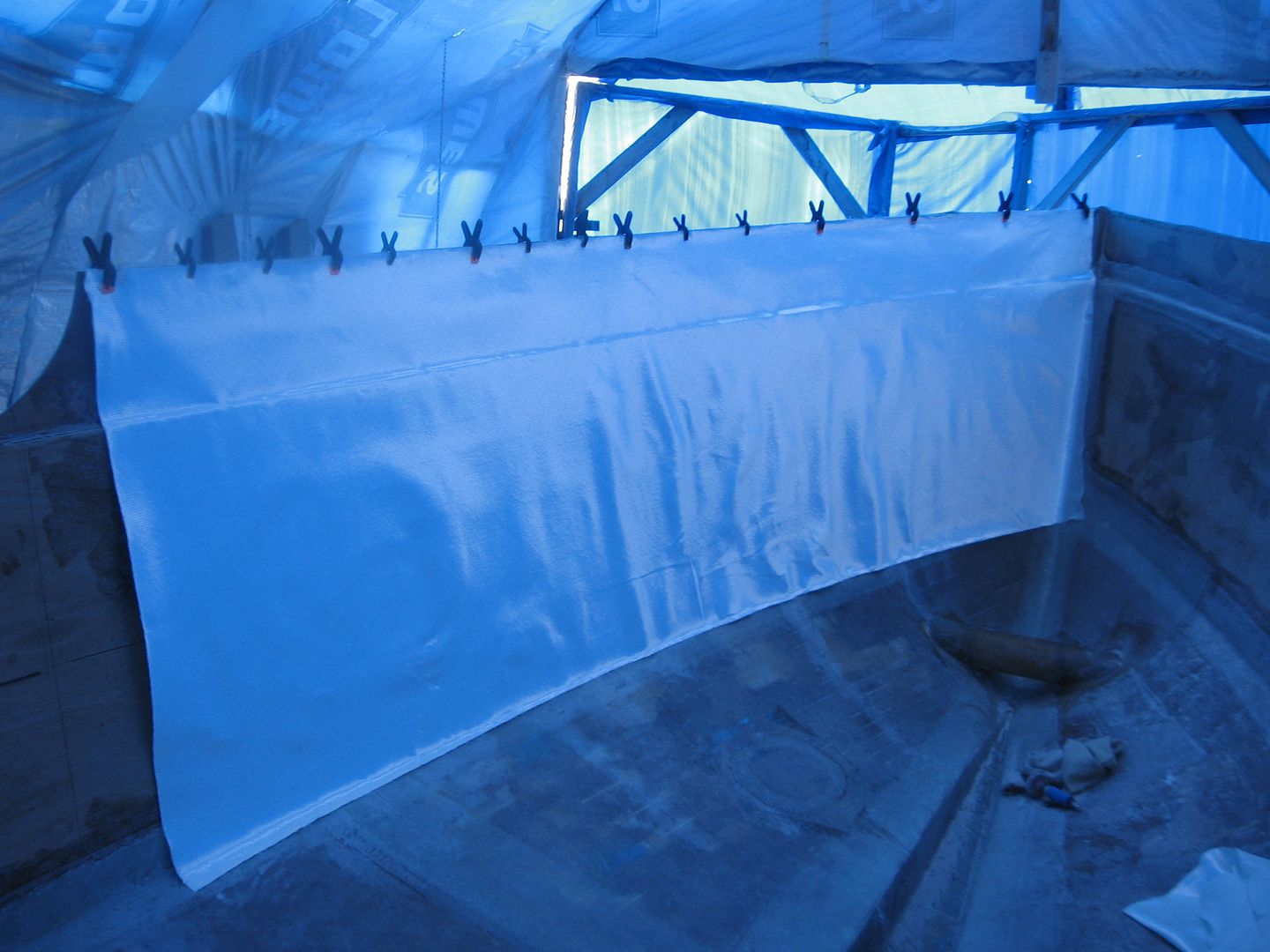

A 16 foot by 4 foot! Yikes, you are one ambitious person, I wish you luck!

I hope the cars ok keep up the good work on the boat