Yesterday

Petty Officer 1st Class

- Joined

- Feb 21, 2012

- Messages

- 354

Re: War with lower unit

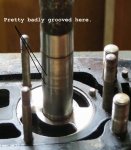

As for the water pump, something didn't sit right with me about this so I started looking for OEM pictures of the original. It looks to me like a chunk of plastic from the pump housing has melted down into the pump around the drive shaft, though if so it left a remarkably clean hole. My present theory is that this may have been the original cause of the water getting into my shaft housing and why there's so much corrosion? The thing is, the drive shaft starts to swell right around that area and the lower the seal surface is to the LU the better chance I have of getting a good seal. Both sierra and Mallory's after market pump housings seem higher up if anything, so I don't know what to do with this situation. Any advise would be appreciated. Also: Should this be a new topic? I'm not sure of the forum's protocol in this sense.

As for the water pump, something didn't sit right with me about this so I started looking for OEM pictures of the original. It looks to me like a chunk of plastic from the pump housing has melted down into the pump around the drive shaft, though if so it left a remarkably clean hole. My present theory is that this may have been the original cause of the water getting into my shaft housing and why there's so much corrosion? The thing is, the drive shaft starts to swell right around that area and the lower the seal surface is to the LU the better chance I have of getting a good seal. Both sierra and Mallory's after market pump housings seem higher up if anything, so I don't know what to do with this situation. Any advise would be appreciated. Also: Should this be a new topic? I'm not sure of the forum's protocol in this sense.