Monterey276

Seaman Apprentice

- Joined

- Aug 11, 2023

- Messages

- 36

Lol thanks, well I guess I’ll put them back in thenusually the easiest way is to remove the drive before removing the motor.

Lol thanks, well I guess I’ll put them back in thenusually the easiest way is to remove the drive before removing the motor.

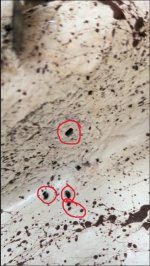

Yea, that’s what I’m thinking too. I think after I take some real accurate measurements of everything in there. I’m going to cut off the top glass layer above both bunks. That will be a start to see how they were constructed and how I’d need to rebuild. I’m scared to find out how far up it goes. How was the water getting in there???Those bunks with the holes already in them have likely been wet a long time. I doubt the holes you found there chalked over were part of the original design. There is likely water soaked foam in there as well. They have to come out and be replaced IMO. I'll admit the transom don't look too bad so that's a bonus.

It is really solid. To give you an idea of the condition, I had originally planned to cut off the inner transom skin in 2-3 sections. I was going to epoxy back in place after I did the repair work. It was bonded so tightly to the wood that I had to cut into small sections and pry off with a hammer and 2’ prybar. The transom is the least of my concerns right now.Is the transom wood wet? but not rotted? I can see it is dark in a few places, but you can probably kill it if the wood is still solid.

Letting it all dry (really dry out) out before you glass back over will be important.

I’m not getting into it until next year anyway. My goal for the fall is to just identify/expose what needs replacing. Then I’m going to put a bunch of damp rid buckets inside and wrap the boat for winter.Transom looks wet.

Would be months faster just replacing than trying to dry it and kill the mold spores

Lucky me ehh. I’m the guy stuck doing it the right way…The biggest joke in regard to boat compartments is that they are sealed and waterproof. Guys still rehab boats and think these non air non drain compartments won't fail. LOL

They always fail mostly from mfg's cheap ass jobs and prior owner band aiding the problem and passing it off at sale as dry.

Guud Luck.

When you rebuild them, I would leave a drain hole at the lowest point and coat the inside with resin to seal the wood, then fill the cavity with rigid subsurface foam insulation. That way any water that gets in there in the future can get out. Like was said, give it enough time and water always gets in!Lucky me ehh. I’m the guy stuck doing it the right way…

When you rebuild them, I would leave a drain hole at the lowest point and coat the inside with resin to seal the wood, then fill the cavity with rigid subsurface foam insulation. That way any water that gets in there in the future can get out. Like was said, give it enough time and water always gets in!

Yea, that is in the plans for sure. Not exactly sure how I’ll design it but I’ll figure it out once I deconstruct what is currently there. I’m certain some of the water was allowed to pass through all the stainless screws holding down electrical/mechanical components. I have an idea that if I rebuild them with something 1” thick (maybe 2 sheets of 1/2” marine plywood bonded together) and then only use 3/4” stainless screws for reattachment points, there wouldn’t be any piercings into the new bunks. I’d also predrill any holes I need with a larger diameter, refill those holes with thickened epoxy, then finally, drill the 3/4” screw holes to attach my equipment. Lots of extra steps but I’m not cutting corners on this project.When you rebuild them, I would leave a drain hole at the lowest point and coat the inside with resin to seal the wood, then fill the cavity with rigid subsurface foam insulation. That way any water that gets in there in the future can get out. Like was said, give it enough time and water always gets in!

Another option would be to use coosa board or some other composite material that won't degrade if it gets wet.Yea, that is in the plans for sure. Not exactly sure how I’ll design it but I’ll figure it out once I deconstruct what is currently there. I’m certain some of the water was allowed to pass through all the stainless screws holding down electrical/mechanical components. I have an idea that if I rebuild them with something 1” thick (maybe 2 sheets of 1/2” marine plywood bonded together) and then only use 3/4” stainless screws for reattachment points, there wouldn’t be any piercings into the new bunks. I’d also predrill any holes I need with a larger diameter, refill those holes with thickened epoxy, then finally, drill the 3/4” screw holes to attach my equipment. Lots of extra steps but I’m not cutting corners on this project.