You got a great deal, congrats!

Prior to pulling anything apart, AD had a great idea of checking the proper firing order and then from there, start it up at that 1000 RPM ‘idle’ and pull (one at a time and then put back) each spark plug wire from the plug. Pull it off completely not just a little bit as the plug could still fire. What you are expecting (hoping for) is that for each plug the RPM should drop the same amount. Giving your compression test results, I would start with nos. 2 and 3 and then go to 1 and 4 as I expect it will stall when pulling 1 and 4.

Yes, I have done head gaskets. Cost could be a little as a new gasket, i.e. nothing else is wrong and put on a new for $30. If the head is cracked due to a possible overheat (which also blew the head gasket), well, then a lot more.

My suggestions:

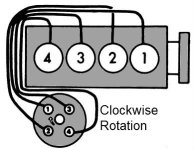

- Confirm firing order (FO)

- Do the pull the plug off test

- If FO is good and the pull off test shows 2 and 3 not pulling their weight (no significant drop in RPM) then:

- Do some research about how to pull head as well as for parts > this will get you into the mindset.

- Evaluate what tools you have / will need. Note I consider any new project a great excuse to buy tools! We can help advise on tools as well, but again trying to get you into the mindset.

- Determine what sort of budget you are willing to apply to this. Recall you also still must do maintenance to the drive, so that will be some $.

- Post the results of the FO and pull of test and we’ll keep going. Its easy, you can do it so fear not!

Ah, to be young again… I had my first boat when I was 19 and living in Stockholm, Sweeden in the 70s where there was a ratio of 1 boat for every 2 people, or so I was told and it sure seemed like it. It was a blast!