Re: 1973 Starcraft 15.5ft unknown model AMBITIOUS restoration

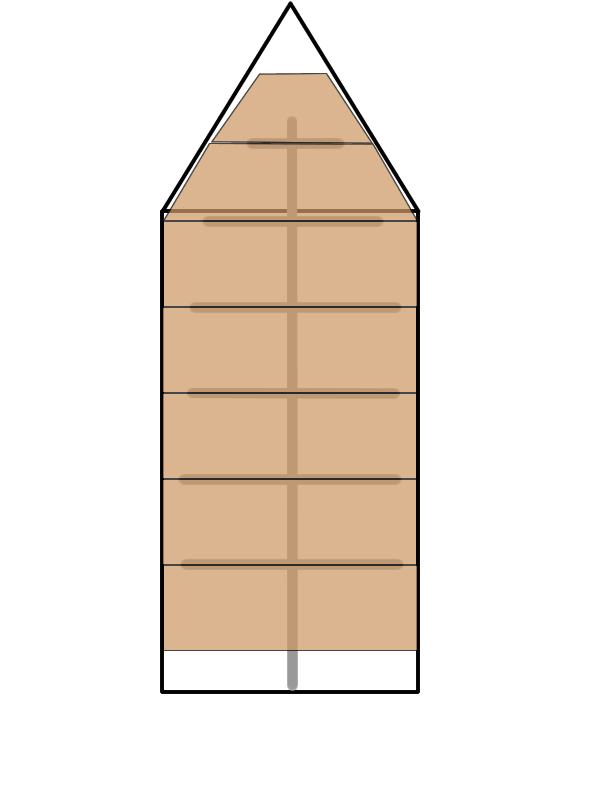

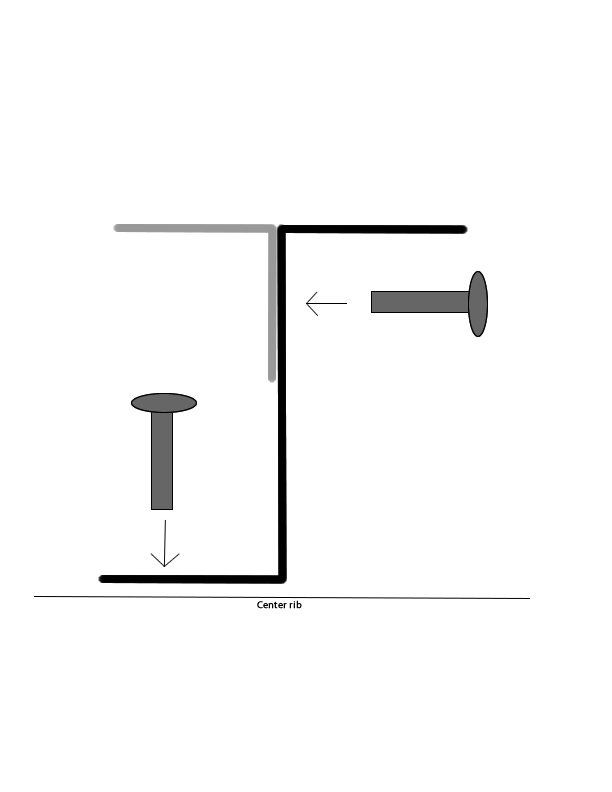

I don't know for sure how your Z section and the aluminum stringers were arranged before your demolition job but they didn't look like your drawing in my 14 footer. In my boat, the Z section runs fore-aft and is riveted through the bottom into the tops of each rib. From the pictures you posted, the Z section is also fore-aft and I can see the holes in the top of the ribs along the centerline where it was attached so I think your boat is put together just like mine. I don't have anything that I'd call a "center rib" as you've labeled in your sketch but if you meant the

center of the rib, then the orientation of the Z section is fine. The stringer is going the wrong way though. My stringers run port to starboard, not parallel to the top of the Z section. They weren't riveted to the Z section other than as part of a sandwich where the floor covered the stringer and there was a rivet down through the floor. I'm not good with any drawing program but I've attached a couple pictures of my boat during demolition (note the 24 years of crud on the bottom) showing the Z section layout and the two stringers. The first picture is of the aft end looking starboard, and only the aft most floor section is removed. You can see the end of the Z section and half of the stringer (the other half is still under the next floor section) on the left side of the picture. The rivet hole at the end of the Z section is from a floor attachment rivet. There are no rivets going through the vertical part of the Z section. The second picture is with the floor all out looking forward. The forward stringer is still in but this part of the picture is kind of dark (sorry), but you'll get the idea.

The stringers on my boat were thin aluminum plates, about 4" wide by about 4' long and are riveted to each edge of the floor panels they joined. Unfortunately, I've never seen this kind of material in your normal hardware stores or HD or Lowes. You could use thin angle sections, but you'll have to break the stringer where it meets the Z section and you'll have to make it short enough (or taper it) so that it doesn't interfere with the ribs out toward the edge of your floor. I happened to have a couple scrap pieces from an old project laying around that were thin and flat so I used them for the new joint I added to my floor. To be honest, I think the stringers could be made from wood as long as you sealed the stringers too, but you'd still have to have a break where they crossed the Z section. I don't think that's a problem though since they just join the floor sections and don't provide any strength.

Good luck, 1988 Starcraft