Re: 1976 Century Arabian - Mercruiser 888 - Boat Restoration

...as I was saying. Not sure how to just cancel a post once I started it.

MM, not sure how pulling out some poundage during the rebuild would change the vessel dynamics. Currently, the 22 gallon gas tank is in the bow and there isn't a great deal of change in the feel between full and empty, so that is a weight change of approximate 120 lbs (this might be an argument not to worry about weight?). What if I could pull out another 80-100lbs. The stern sits pretty flat where the engine sits so she seems pretty stable.

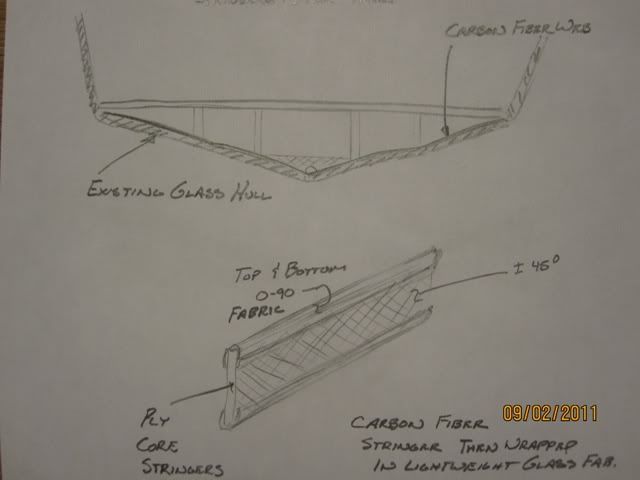

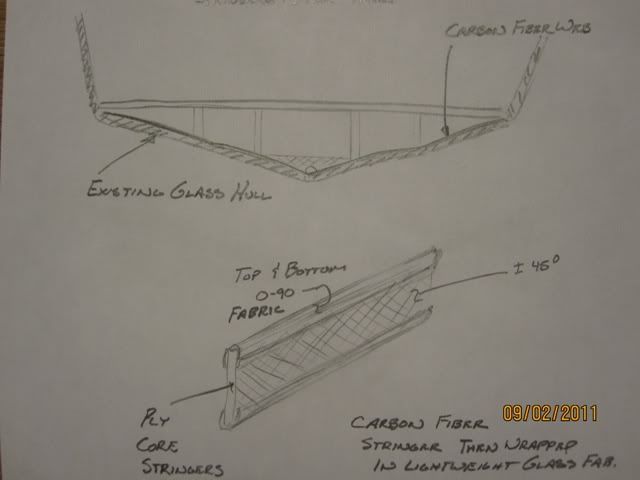

When I look at a transverse cross section through the hull it looks just like a truss. What if I lined the inside of the hull with a carbon fiber weave oriented 0-90 from stern to bow to behave as a stiff web attached (bonded with epoxy) to the bottom side of the stringers. As pressure from the water loads the web, the truss will absorb it, as it should. I could really stiffen the structure up by wrapping carbon fiber in the stringers oriented +-45 on the sides with bottom and top caps running 0-90 (considered using unidirectional on top and bottom). My thinking is the existing fiberglass hull just goes along for the ride and absorbes impact damage.

I'm thinking out loud here...

I sketched this out

...as I was saying. Not sure how to just cancel a post once I started it.

MM, not sure how pulling out some poundage during the rebuild would change the vessel dynamics. Currently, the 22 gallon gas tank is in the bow and there isn't a great deal of change in the feel between full and empty, so that is a weight change of approximate 120 lbs (this might be an argument not to worry about weight?). What if I could pull out another 80-100lbs. The stern sits pretty flat where the engine sits so she seems pretty stable.

When I look at a transverse cross section through the hull it looks just like a truss. What if I lined the inside of the hull with a carbon fiber weave oriented 0-90 from stern to bow to behave as a stiff web attached (bonded with epoxy) to the bottom side of the stringers. As pressure from the water loads the web, the truss will absorb it, as it should. I could really stiffen the structure up by wrapping carbon fiber in the stringers oriented +-45 on the sides with bottom and top caps running 0-90 (considered using unidirectional on top and bottom). My thinking is the existing fiberglass hull just goes along for the ride and absorbes impact damage.

I'm thinking out loud here...

I sketched this out