steely85

Petty Officer 2nd Class

- Joined

- Apr 18, 2015

- Messages

- 121

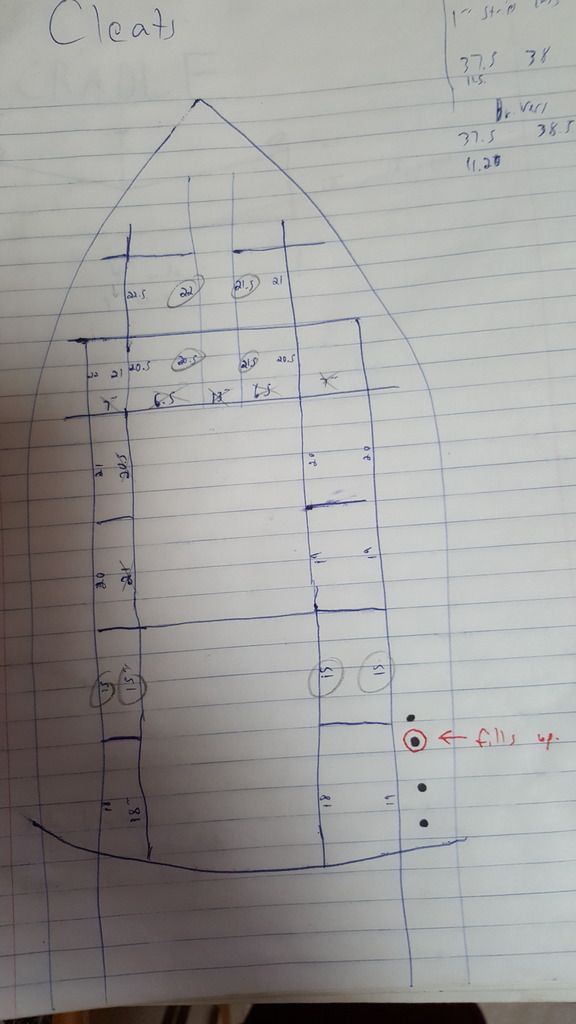

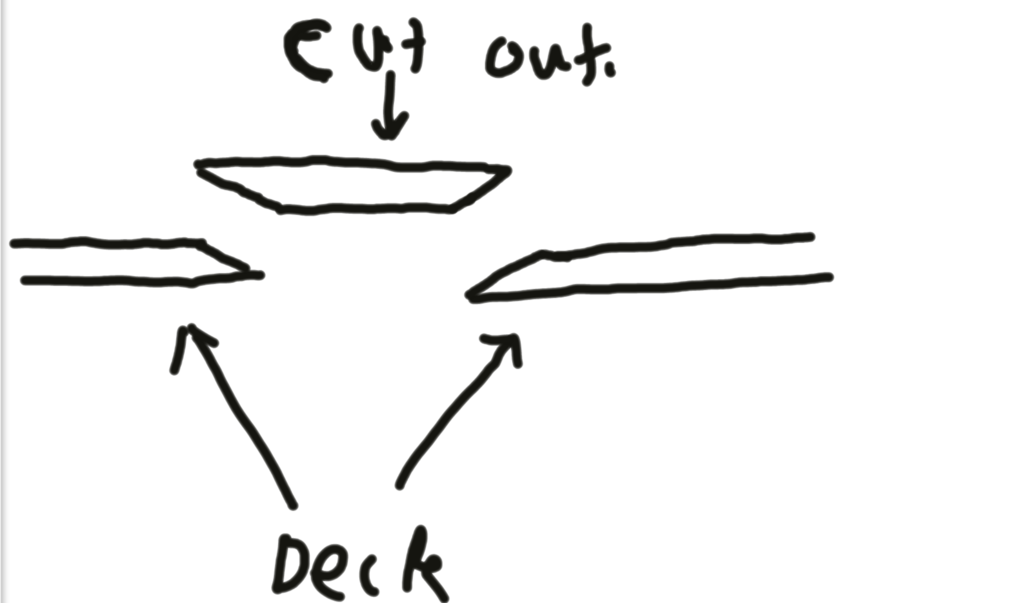

So here is my idea for the front seat boxes. Instead of replacing the front floor tub I don't want there to be a step up into the front of the boat. I want it to be nice and flat. So instead I will take plywood and notch one side about 4 inches using my table saw and gluing it to the fiberglass of the seat boxes. here is a crude illustration.

The plywood would also be glued to the floor making the front seats one with the floor.

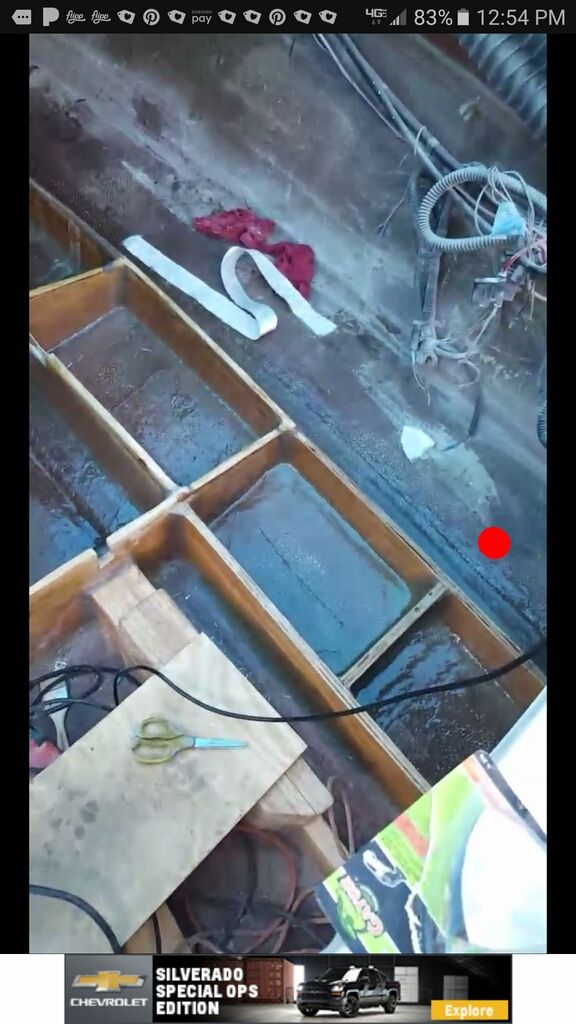

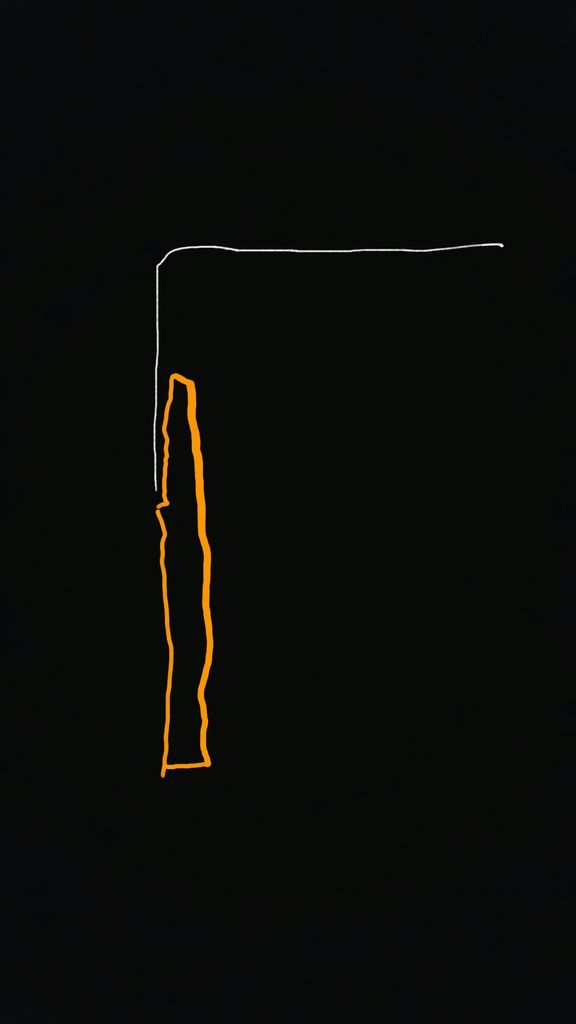

Here is an example using a 2x4 piece of wood held up to the front seat wall.

I'll also bolt theme together so hopefully the bond won't crack or break. It will be covered by trim so I am not worried about making it beautiful as much as sturdy.

The plywood would also be glued to the floor making the front seats one with the floor.

Here is an example using a 2x4 piece of wood held up to the front seat wall.

I'll also bolt theme together so hopefully the bond won't crack or break. It will be covered by trim so I am not worried about making it beautiful as much as sturdy.