I purchased this closed cooling system from the same vendor as the engine, and though it was really close, it wasn't quite the one needed. There are a lot of slight differences between the individual installations of the many boat manufacturers, so it's understandable that variations are inevitable. I called Seakamp directly to talk about my problem, and was rewarded with some amazing customer service. I spoke with one of their techs at great length, and with his help, was not only able to solve my remote oil filter interference problem, but also make a slight improvement in the routing one of the hoses. The Seakamp tech sent me elbows and hoses, and actually fabricated a 3/4" to 1" elbow for me to make everything work. I was impressed.

I needed a little more space to route one hose around the filter so I added several stainless washers to move the remote oil filter aft a bit.

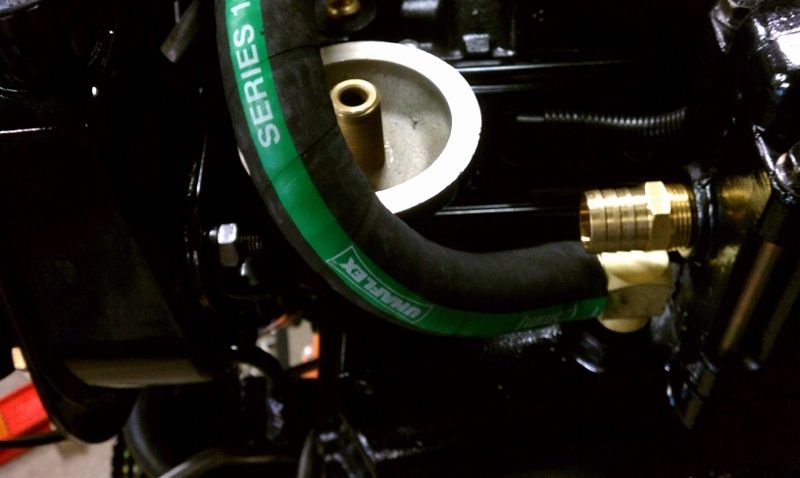

By replacing a straight fitting with an elbow, and moving the "T" aft, I was able to get everything working perfectly.