eboat85

Petty Officer 2nd Class

- Joined

- Sep 1, 2013

- Messages

- 121

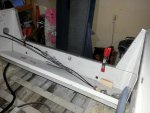

85 Crestliner 16 Project

85 Crestliner 16 Project

JB,

I gave it a try and it looks like it only has an effect on the current post and not the entire thread. I changed the first post and that too only changed that one. It might however reflect on any responses to the posts. In the mean time I am going to keep using this title ^^^^^.

Thanks for trying!

85 Crestliner 16 Project

JB,

I gave it a try and it looks like it only has an effect on the current post and not the entire thread. I changed the first post and that too only changed that one. It might however reflect on any responses to the posts. In the mean time I am going to keep using this title ^^^^^.

Thanks for trying!