MountaineerMiner

Petty Officer 2nd Class

- Joined

- Mar 9, 2010

- Messages

- 146

Re: 87 Glassport rebuild, 16.5'

Thanks guys! Tonight I finished fitting the first piece of ply for the transom and cut out a piece for the "bump out" where the drive bolts. After doing so I decided it would be best to add a full second sheet as it will be much easier to glass and provide a little more rigidity. I will try to get a couple pics tomorrow. This decision was also made after handling 1708 for the first time. I knew it would be a pita to shape around those hard angles.

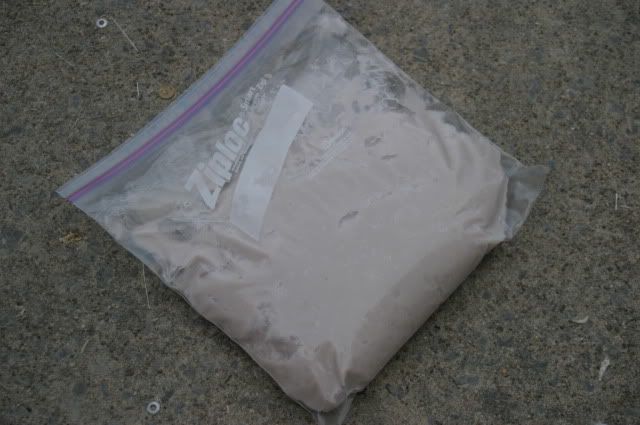

I also got a present from the guy in the brown truck today...I helped him unload it and could smell the resin before I got in his truck. He said he decided to stop by my place after his day was over and see if I was home so he wouldn?t have to ride around with that smell again! I know this stuff stinks but I never had a 5 gallon bucket of it before.

What are the recommended handling instructions for poly resin? I figure protect from freezing is one, but are there negative consequences to heat exposure? Also I believe it was in Oops thread that he mentioned grinding or roughing up the hull a second time because it had set to long. Am I mistaken or is there a certain time frame I have between roughing up the old fiberglass surface and laying new resin?

Mike

Thanks guys! Tonight I finished fitting the first piece of ply for the transom and cut out a piece for the "bump out" where the drive bolts. After doing so I decided it would be best to add a full second sheet as it will be much easier to glass and provide a little more rigidity. I will try to get a couple pics tomorrow. This decision was also made after handling 1708 for the first time. I knew it would be a pita to shape around those hard angles.

I also got a present from the guy in the brown truck today...I helped him unload it and could smell the resin before I got in his truck. He said he decided to stop by my place after his day was over and see if I was home so he wouldn?t have to ride around with that smell again! I know this stuff stinks but I never had a 5 gallon bucket of it before.

What are the recommended handling instructions for poly resin? I figure protect from freezing is one, but are there negative consequences to heat exposure? Also I believe it was in Oops thread that he mentioned grinding or roughing up the hull a second time because it had set to long. Am I mistaken or is there a certain time frame I have between roughing up the old fiberglass surface and laying new resin?

Mike