Re: '93 Monark Pro 1900 rebuild

Whelp, this is my experience with vinyl:

http://forums.iboats.com/boat-resto...ir/97-tracker-pro-deep-v-facelift-509163.html

... and as far as I'm concerned there's only one way to put vinyl on aluminum pieces like that, and that way is to use Weldwood Contact Cement:

The bond and holding power is immediate which is real important when working with vinyl on metal. Vinyl is very unruly when trying to use the slower bonding/curing adhesives on metal because it naturally wants to curl back to the shape it was in on the roll. The contact cement tames it nicely and it stays put when you apply it.

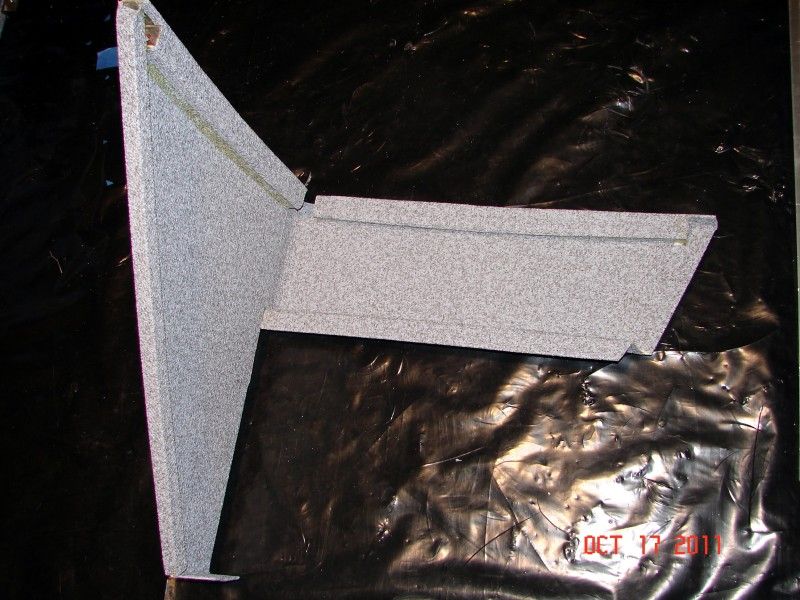

That piece you show in the last pic aint diddle-squat for the contact cement to hold, take a look at this piece I did:

That's my steering console base with all kinds of bends and a nice radius. The contact cement whipped that things butt!

Two tools you can't do without when doing vinyl are these two rollers:

They roll out any and all air bubbles (and you'll have those, believe me) and they also embed the vinyl backing into the cement. The big one is a hand held carpet roller and the small one is a laminate "J" roller. You'll use the big one for large areas and the little one for for smaller pieces and those hard to get into bends and crooks. Both rollers are available at Home Depot, the big one in the flooring dept and the little one in the cabinet dept.

When applying the contact cement, apply it to both the vinyl and the aluminum. Apply one coat to the vinyl first, then a coat on the aluminum, then a second coat to the vinyl... the vinyl backing is porous and will absorb the first coat while you're coating the aluminum, so a second coat is needed on the vinyl. The aluminum is fine with just one coat.

Buy a gallon of the contact cement, about $40 at Home Depot, you'll probably need more.

Apply the vinyl to your smaller pieces first to get the hang of working with the contact cement before tackling the larger pieces.

Make sure to cut your vinyl pieces big enough to wrap the vinyl around the back of each piece by 1-1/2" - 2" like this:

Vinyl has a directional grain just like carpet so you have to be careful and to which way you turn it when applying it. To make this easy I designate one end of the roll of vinyl as the "bow of the boat" and mark "bow" on each piece of vinyl and each piece of aluminum or plywood to help keep the vinyl turned the right way for everything.

If you have any questions just give a holler.