Re: Advice please! Fiberglass boat hull hole patch (pics)

I like that nice looking job.

Now how many layers did you lay up at a time and did you impose any type of weight compression or such upon these layers while in the cure out phase?

The whereabouts of this patch that i am needing to create really needs to be extra strong due to it's whereabouts when sitting on the boat trailer and so i do not need, neither do i want, any air voids contained within the layers. What did you do to prevent this from occurring?

I am concerned with polyester resins as for their shrinkage characteristics, i am not sure as to whether or not with a hole the size of mine (5" x 12") if that should even be a concern of mine. Not sure, never messed with much fiberglassing before.

I know i can do it however, not any worries there, just trying to obtain all the necessary information that i need before i begin the process.

Plus now i have this whole mental dilemma - debate if you will - going on trying to determine what system i need to use

Polyester Resins

West System epoxies

Vinyl Resins

I am still researching at present.

Thanks guys for all of your help/replies

Chris

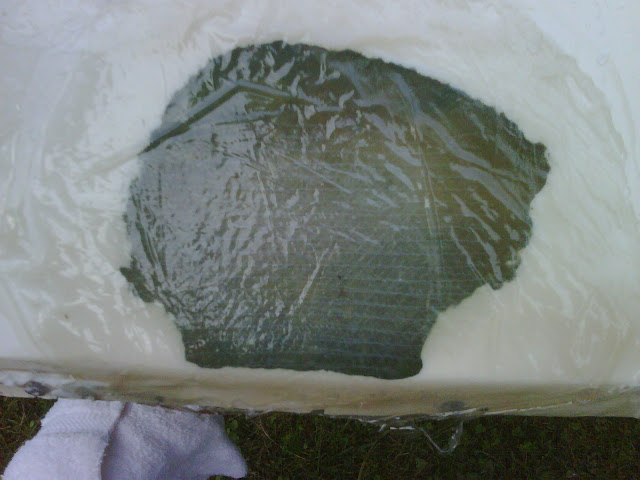

that's what I did on this patch using polyester resin. I wet out all 6 layers on a piece of plastic, and then brushed resin on the boat, put the patch on like a big bandaid and rolled out the patch with the plastic on top of it, and let it sit overnight with the plastic still on it. If I had worked a little harder, I could have gotten a prettier outcome, but I still had to grind it down smooth regardless. I rolled out quite a bit of extra resin to make the patch relatively lean, but still fully saturated.

I like that nice looking job.

Now how many layers did you lay up at a time and did you impose any type of weight compression or such upon these layers while in the cure out phase?

The whereabouts of this patch that i am needing to create really needs to be extra strong due to it's whereabouts when sitting on the boat trailer and so i do not need, neither do i want, any air voids contained within the layers. What did you do to prevent this from occurring?

I am concerned with polyester resins as for their shrinkage characteristics, i am not sure as to whether or not with a hole the size of mine (5" x 12") if that should even be a concern of mine. Not sure, never messed with much fiberglassing before.

I know i can do it however, not any worries there, just trying to obtain all the necessary information that i need before i begin the process.

Plus now i have this whole mental dilemma - debate if you will - going on trying to determine what system i need to use

Polyester Resins

West System epoxies

Vinyl Resins

I am still researching at present.

Thanks guys for all of your help/replies

Chris