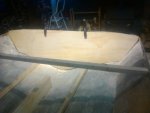

Re: banshee transom and likely stringers

No worries on the transom gaps, that is what the PB is for...think of it as tile setting compound that is used to raise all the tiles to an even level, some places you use a little more, some less...

Good looking wood work so far...btw...

As to using the blue/pink foam, Yes, current thinking puts it a notch above the expanding foam as to being much more resistant to water absorption.

The actual unknown/unproven fact remains the actual floatation value of it. At least to me...I think it is closer to a structural type foam due to the fact that it is much denser, which translates to less trapped air...

Another point is whether or not it meets the fuel absorption standard set out by the Coast Guard...I think I have read somewhere that it does, but should be checked by performing a submersion test on a 1" square piece and held under a container of fuel for 24 hours...if it doesn't swell or gain any appreciable weight, it passes...

I have not personally seen a website or link to where it has actually been tested to meet the basic Coast Guard or ABYC requirements.

That is not to say that it hasn't been done or doesn't exist, I just haven't seen the comparison.

Let me add that if someone has a link showing where the blue/pink insulation foam is proven to float as well or better than the expanding foam and meets the other requirements, I am very interested in seeing it.

The use of expanding foam to fill any voids between the rigid foam would seem like an almost futile attempt.

Let me explain my un-scientific reasoning for that statement.

The expanding foam does not stay in a liquid state long enough to actually spread throughout and in between layers of the rigid foam to "glue it into place", and even if it got in between and over enough of it to make a difference, you would still have to provide plenty of vent/pressure relief openings to prevent a blow out or worse, damaging a structural component like a stringer.

The final factor is cost.

I think overall, if the rigid foam performs as well or better than the expanding foam in a floatation sense, the amount needed according to my last calculations and locally available pricing is that the cost between the two is about a wash.

And as a final note, if the rigid foam were a better alternative both cost and performance wise, then I don't understand why boats are still being built using the expanding stuff instead of the rigid...?

You'd think if it was cheaper, obviously cleaner/neater to use/install ( less harmful gases/chemicals/mess) and performed as good or better, then why not use it in modern boat construction that has the floatation requirements as laid out by the CG.

I mean, don't get me wrong, I have seen everything from EPS (Extruded Poly Styrene) to packing peanuts being used as a floatation medium in boats, but the only recommended guideline by the CG is the expanding type...again, as far as I am aware and I have been known to be somewhat under-informed on many occasions...:facepalm: