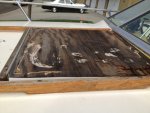

Re: Bow hatches

When I resto'd my own boat it was mainly stringers and deck I replaced. In that instance I used 1708, which is a woven structural fiber glass and CS (Chopped Strand Mat) that is more for wrapping. CSM does not really provide a smooth finish. I was watching an episode of ShipShape TV the other day and they were fiberglassing some old boat they has as a project and they were covering and strengthening a seat structure. Whilst they used 1708 to re-attached it to the hull, they used what they called surfboard mat as it was finer and far smoother than CSM. That could be what you need. There is likely someone on here more knowledgeable than me on this surfboard mat. When you come to resin the plywood, you need to decide whether you will use epoxy resin or polyester resin. Most on here use poly Resin as it's cheaper. Basically what you would do is cut your plywood to shape and make sure all your edges are smooth and have a slight curve to them (no right angles). You then mix your resin with the hardener (you get instructions on the mix). Once mixed you have a given time limit to apply the resin before it goes hard. You would need initially to seal the surface of the wood on all sides and edges with the first coat. When it's dry, you can apply your second coat to one side and the edges and lay down the fiberglass mat. You smooth and bed the mat down into the resin by using either a roller or a chip brush (I never bothered with the roller, just used chip brushes). You can add more resin to the surface to make the seal more effective. The overlapping mat is then wrapped round to the opposite side after the first side has dried. Side 2 is a repeat of Side 1, but you need to do the edges, then wrap the mat round to side 2 and wet it down onto the surface. You can also lay down the mat on the side 2 (cut it smaller) and lay it down on the surface and over the edges of the wrapped mat. Leave to dry and then you can smooth it off with a sander. Gelcoat is the same process as mixing resin, except the resin is the gel coat and you add hardener. You can apply with a roller or brush. Rollers tend to give a smoother finish. The first gelcoat is unwaxed and dries tacky. The 2nd and final gelcoat yu add the wax that comes with it and that dries tack free.

There is another option and that is to use Starboard. This is a plastic composite that doesn't rot, is UV proof. Cuts and sands easily and can be drilled, etc. Downside it is more expensive than plywood BUT before you rile it out add up how much it will cost to buy the plywood, buy the resin and the mat and the gelcoat and the brushes and/or rollers, then compare that total to buying a piece of starboard which all you do is cut to size, screw on the hinge, add the rubber seal and you're done. By the way, you could buy rubber seal from HD or Lowe's that is self adhesive, so no cutting out channels on the underside.