No Title

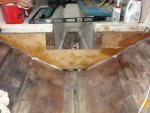

Hey Guys, couple of questions. I have these boxed fiberglass sections that run along the path of the chines on the inside of the hull. They are about 3 to 4 foot long but the ends are open which has rotted out the core. I can't see how they add any real strength to the hull and want to cut them out. I see in Ahmincha's post that he filled in the chine areas. Do I need to do the same and what benefit will I get if I do it? My thought right now is to cut them out, grind down flat and add another stringer. Will doing it with the second stringer be a better option, opinions please.