Re: Finally began my summer project and I am already confused...

Great instructional video. A pour-in transom seems like the only way to go to avoid popping the cap. What is the general method used to attach the stringers to the transom?

Will the nida bond to the stringers on its own? If so, then how do you protect the stringers from future water intrusion??

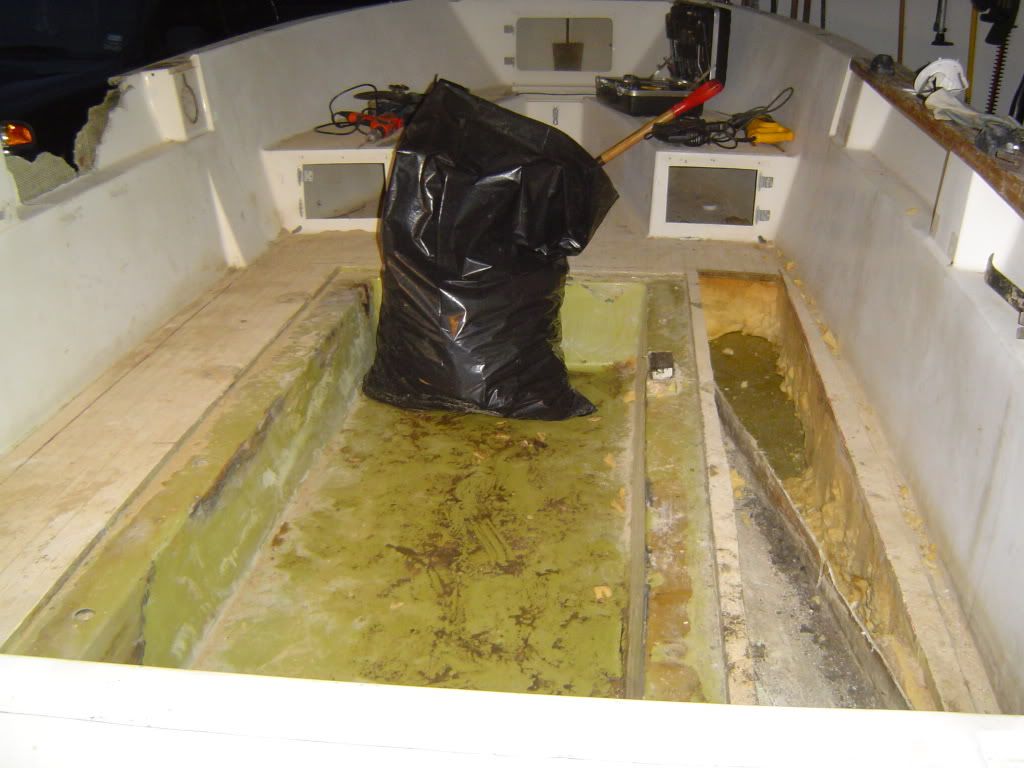

The problem is standing water, lack of drainage , foam.

A lot of us are using PL premium construction adhesive to bed the stringers to the hull, stringers should not touch the glass, they need to be spaced 1/4 inch off the glass. Then resin and glass over the stringer to the hull, themselves could be composite foam., stringers But those tend to be expensive, wood is fine if its PT and sealed properly with proper drainage.[

see pic, the strength comes from the glass over the stringer

This is a bad install without bedding.

Below is a good installation where the stringer is spaced away from the glass hull, this prevents spider cracks in the outter hull gelcoat.

On mine, I trial fitted the stringers then pre-glassed them outside the boat for convenience with unwaxed poly resin, then I only had to tab them to the hull after bedding with the PL, I find it quicker and easier to glass a stringer on 2 trashcans compared to working on my knees inside the hull.

The PL allows 30 minutes work time so it makes positioning easier, after it cures for an hr just finish glassing stringer to hull.

Knee braces are a good way to transmit loads at the stringer to transom joint, I did mine similar to this,

They need limber holes to allow drainage between compartments, its easier if done first before install and seal the wood real good with resin, multiple apps until the wood grain is drenched and saturated with resin because thats the likely point of entry.