Re: hull extension in progress with picks

Re: hull extension in progress with picks

Yeah... sounds like you dodged a bullet here.

I would think that considering what you've done so far, you have the skills to make the cutout and mount the drive yourself. It's not too hard.

You just need to spend some time measuring the transom that you have in the boat, and figure out the motor mount height and where to put the hole.

Essentially the transom hole sits a certain height over the bottom of the boat so the lower leg is at the right height. Obviously having the drive centered is good, but it's not 0.001 precision or anything. Both my boats have had transom holes that looked ok but measured as about 1/4" off center. Remember that boats with twin sterndrives can operate on one drive as much as three to four feet off center and the boat still goes forward. The ability to trim the drive with the zinc rudder tab will let you center the thrust enough to compensate for a missed angle.

Even the lower leg height isn't critical.. if it's way off you'll have more cavitation than you want, but that's about it. You're trying to put the cav plate at a height close to level with the hull bottom.

I'd work to make sure the hole is perpendicular to the keel, then make sure it puts the lower leg at the right height, then make sure it's centered, in that order. Again, you can be off as much as 1/4" and everything will work fine.

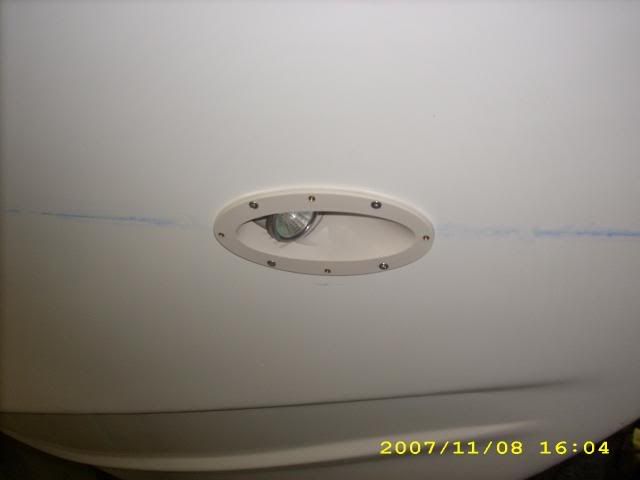

Cut the hole very carefully though.. the bolt holes and size must be exact per the template, and then make sure you're gonna end up with a transom the right thickness. Seal the edges of the hole with thin glass and resin.

Once you cut out the hole, then you'll know where the transom plate goes. You can test fit the motor if you like, based on the transom plate height and angle you know how much to modify the motor mounts to put the engine at the right approximate height and *close* to the right vertical angle.

You already cannot alter the left/right angle of motor mounts to transom... that's determined by the angle of the transom. The transom plate attaching to the motor mounts on the flywheel cover gives you the left-right angle you need, and the transom plate is bolted to the transom (obviously).

Then you adjust the motor mounts (front) vertically to give you the precise angle you need between coupler and the leg's input shaft.

All the dimensions and angles that are super critical for correct engine propulsion are non adjustable except for that vertical angle, which you set with your alignment tool. Although the transom hole has to be the right shape and the transom thickness is important, since the entire rest of the drive train hangs off the transom kit, it'll all line up.

Just make your best measurements and pick a location.

With a 4.3 you'll be able to try out the hull, but I think it'll be way underpowered for a boat that size/weight, so keep that in mind while you try it.

Erik