good afternoon all; i need your kind support please. in this days i installed my motor heads and i was in about to install valves lifter and i had a big issue.

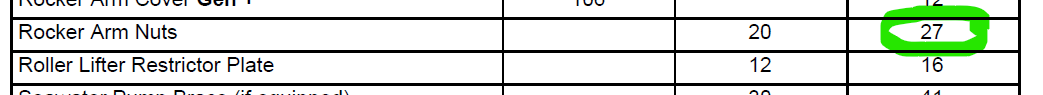

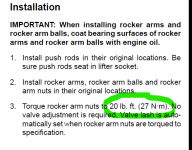

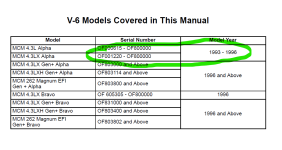

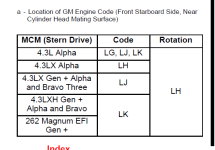

on manual #18 ( mine is 4.3 lx 1995) and here in the forum i sow that for my model ( with balancer shaft ) i don't have to perform the 0 clerenace on push roads +3/4 of rotation for valves registration but as per manual roket arm need to be closed at right torque ( 27 nm) .

after installation i torque the roket arm at 27 nm but i sow that after one complete revolution valves was opening ( the push roads was not loading the lifter but was bloked so the valves opened as consequence)

i removed the lifter and i sow that i could not push the lifter down.

i disassembled all the lifter and i cleaned in ultrasonic device.

after that installed back the lifter with no oil i can push the spring properlly so i assueme that now i can tight the roket arms at 27 nm without issue ( but i can push quite easyly)

i did also a test, i open again one lifter, i put some small amount of oil inside the lifter before assembling and try again with same resoult of before cleaning ( no compression allowed due to oil )

accordingllhy to what i understud the inside part of the lifter has a no return valves. when motor is on, pressure goes on and oil goes inside the lifter, and gose trought the no returne valves and get the lfter hard just allowing same small movement ( 0,1 mm) to allow thermal compensation.

i need to understand, how i should proceed ? shell i install all lifter totally empty as now tight 27 nm the roket arm and switch on the motor? how the lifter will be filled by oil? i left them on motor oil for 2 days but without pressure the not return valves can not open so oil will not fill them inside.

sorry for long message, i hope i could explain it properlly but which one is the right methid to install this?

ps ( i have installed EFI cams )

on manual #18 ( mine is 4.3 lx 1995) and here in the forum i sow that for my model ( with balancer shaft ) i don't have to perform the 0 clerenace on push roads +3/4 of rotation for valves registration but as per manual roket arm need to be closed at right torque ( 27 nm) .

after installation i torque the roket arm at 27 nm but i sow that after one complete revolution valves was opening ( the push roads was not loading the lifter but was bloked so the valves opened as consequence)

i removed the lifter and i sow that i could not push the lifter down.

i disassembled all the lifter and i cleaned in ultrasonic device.

after that installed back the lifter with no oil i can push the spring properlly so i assueme that now i can tight the roket arms at 27 nm without issue ( but i can push quite easyly)

i did also a test, i open again one lifter, i put some small amount of oil inside the lifter before assembling and try again with same resoult of before cleaning ( no compression allowed due to oil )

accordingllhy to what i understud the inside part of the lifter has a no return valves. when motor is on, pressure goes on and oil goes inside the lifter, and gose trought the no returne valves and get the lfter hard just allowing same small movement ( 0,1 mm) to allow thermal compensation.

i need to understand, how i should proceed ? shell i install all lifter totally empty as now tight 27 nm the roket arm and switch on the motor? how the lifter will be filled by oil? i left them on motor oil for 2 days but without pressure the not return valves can not open so oil will not fill them inside.

sorry for long message, i hope i could explain it properlly but which one is the right methid to install this?

ps ( i have installed EFI cams )