- Joined

- Jul 23, 2011

- Messages

- 52,084

if your rocker studs look like this, then the head is set up for non-adjustable valve train. you tighten the nut until it bottoms out and then torque to 20 ft-lb (27 Nm)/ you have just a nut and the rocker on a trunion

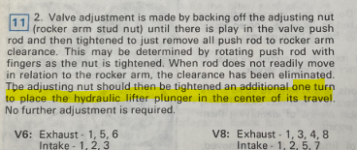

if the rocker studs look like this, then they are for adjustable valve train. then each cylinder is brought to TDC and you tighten the nuts to 3/4 turn past zero lash. this will have a ball, nut, and rocker.

if the rocker studs look like this, then they are for adjustable valve train. then each cylinder is brought to TDC and you tighten the nuts to 3/4 turn past zero lash. this will have a ball, nut, and rocker.