PlayD0h

Petty Officer 1st Class

- Joined

- Apr 23, 2009

- Messages

- 331

What's the question?

We have a lot of boats and boaters, and most/many go from home to lake each use, meaning lots of launches.

Everybody want's easy launching and often the boat needs to be cranked up, tough to do that with bunks.

We do have bunks here but it "seems" they are on high powered speed boats and bass boats.

I "think"? most of the fishing/aluminum are on rollers.

Dan

ps: there are about 850k reg boats and 1.6 million fishing licences in MN, makes for a lot of boats on the roads and lakes

Ah, I gotcha. I was thinking you were referring to the roller ‘bracket’ by ‘support’. I would call those cross-members, but your right about them being easy to contact. I’ve hit the bracket and the support / crossmember at least once.

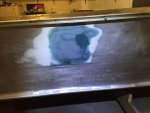

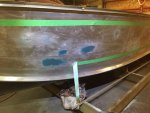

I launch and retrieve 2-3 times a day when I’m camping, and while it’s not ‘easy’ to crank it, it’s also not all that hard. The bogey wheels have made their own little dent in the hull where they sit, and I’d think if each bunk was replaced by 2-3 rollers, they might all dent the hull. Not a huge deal, but I do at times go one some bumpy rough roads.

Without a doubt the majority of fishing aluminum boat trailers around me have bunks. 4 strokes have good low end power and can power up on trailers, and most new boats have 4 strokes here.

I have a spare ATV winch I though of putting on the trailer so the wife can crank me up, or I can with the remote. The winch on my quad has a wireless remote that I never use and I could swap them and use the wireless for the boat.

Im leery of modifying the main structure of the trailer by ‘V’ing’ the supports more, but that’s an option. At the very least I want new bunk boards and the composite ones are something I’d like to check out.

I think Ill leave the trailer design alone for now and just re-bunk it and lose the bogeys for a roller and longer bunks.