So we had a pretty laid back day today and I ended up getting to spend some time working while the kids were napping this afternoon and after bedtime tonight. Before I get into that, here's what I've learned about gelcoat:

1) The solid color stuff really sets up pretty fast.

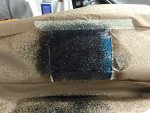

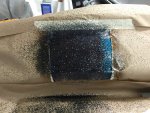

2) I shouldn't have sprayed the blue glitter as high as I did - I ended up having to sand it off of the upper section before adding white. I just looked bad after I added a layer of white to it. I think it was largely due to not having a thick layer of clear yet so it was bumpy.

3) Don't use blue shop towels when wiping everything down with acetone. It ends up making the surface sticky which makes the towel stick and just makes a mess.

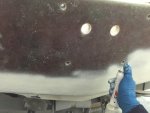

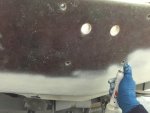

4) Surface prep work is the most important thing you can do. When you start spraying gel coat, EVERYTHING shows up.

5) Body work is just like finishing sheetrock - anyone can put fiberglass on - it takes practice to get it to look nice!

So after seeing all of the pin holes and imperfections, I used some gelcoat mixed with cabosil to make a bondo paste. It worked great. Since it was the same color, it didn't add more work really. The key though was when I remembered that my buddy rgsauger leant me his custom rubber spatula (which he's going to get lucky to get back!!). Oh man, that thing made all the difference in the world. I was able to smooth everything out really nicely. After doing the body work, I sanded down then added a second layer of white everywhere using my 2.3mm HVLP sprayer. I can't say how I had it set because honestly the instructions weren't worth anything so I just test sprayed until I liked it. I did mix in some styrene to thin it just a little since it seemed to be struggling with unthinned. I liked using the sprayer much better than the preval sprayer mainly because I could move faster. The pot time on the gelcoat isn't very long and I had to hurry and clean the gun before it all set up inside.

A note about the sprayer - I read this somewhere then ignored the advice:1) BEFORE you put anything into your sprayer, practice taking it all the way apart and becoming familiar with the parts so when time is working against you, you don't have to stop and read the manual.

2) Have a wash tub with plenty of acetone handy and be ready to wash everything thoroughly.

3) Mix a small batch of gelcoat and start your stop watch. Keep checking it until you notice it start to set up. Stop your stopwatch. That's the max time you have to spray before you risk ruining your gun. Then set a timer each time you spray and when the timer goes off, stop and rinse.

My body work isn't the best and it has big areas of imperfection, but I just ran out of patience in sanding and filling. The structural work is great, but you can tell the finish work is DIY, and I'm OK with that. If nothing else, if someone notices and asks what happens, I'll be able to tell them how awesome I am!!

So, after spraying and filing holes and spraying some more, I will be spraying clear and adding silver flake then more clear over the whole glittery area to thicken it up - it will likely be 2-3 more coats - one being the wax layer to finish it up. I also realized that I needed to add just a tiny bit of silver into the blue and I didn't, so I need to do that as well. Then I will spray one more thick layer of white with wax added for the finish and I should be done with the hard stuff.

Here are pics from today: