nemo2011

Petty Officer 2nd Class

- Joined

- Feb 15, 2011

- Messages

- 157

Re: Repairing stringer

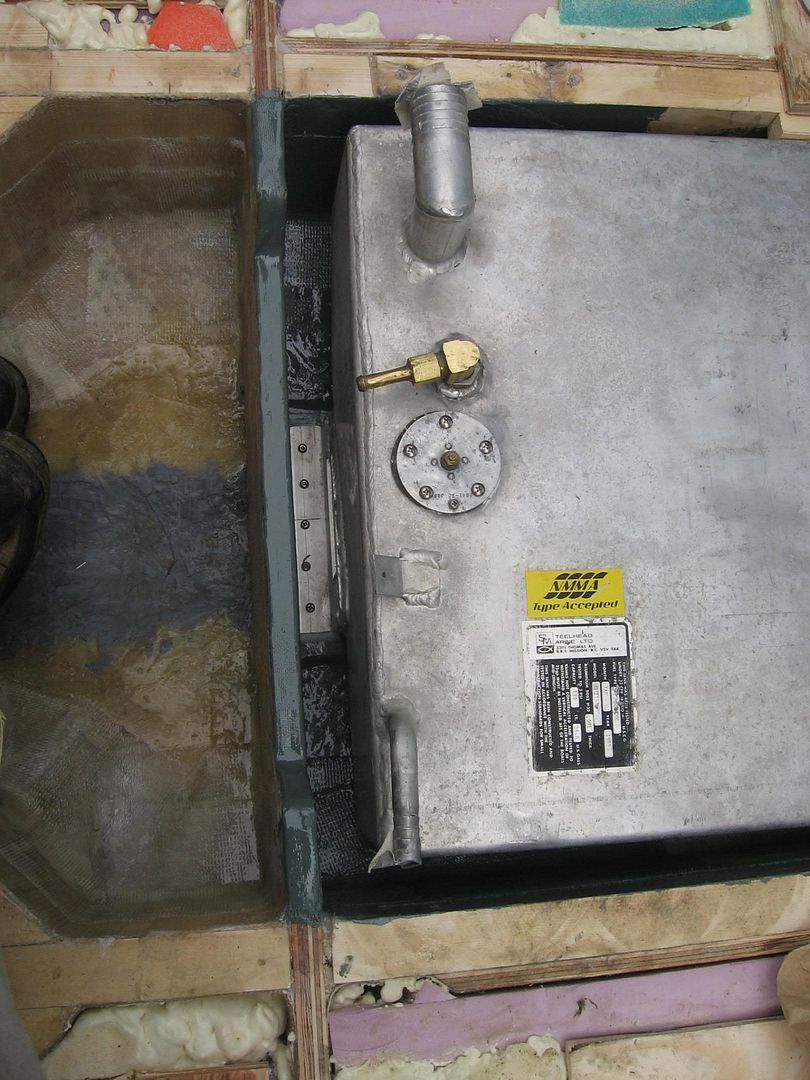

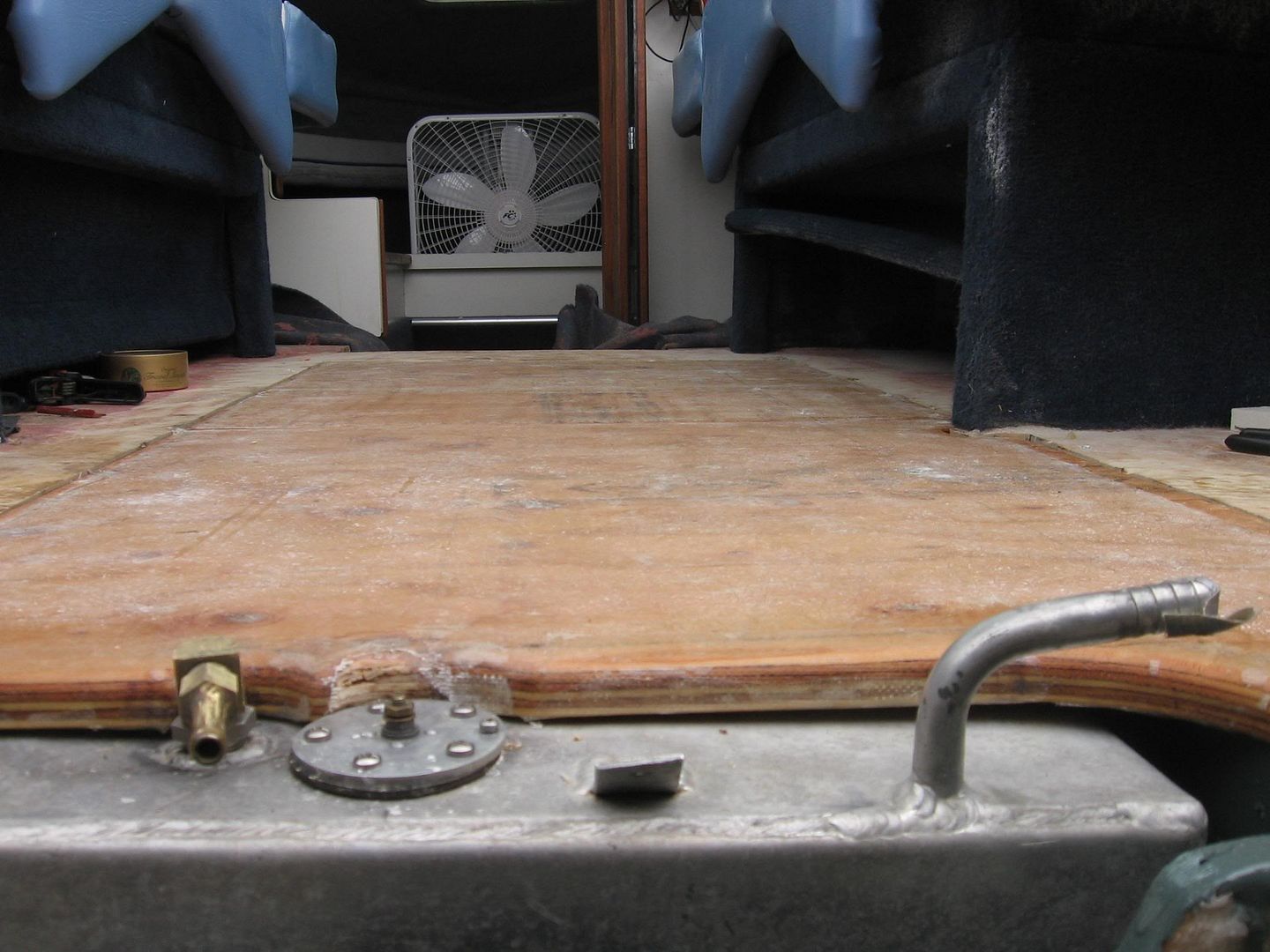

well finally got my gas tank back,looks great with a whole new Aluminum bottom!all for under a hundred bucks.

Tried to prefab as much as I could in the garage stringers,bulkheads,motor mounts etc.

Starboard stringer bedded in peanut butter. I used epoxy to join splices.

well finally got my gas tank back,looks great with a whole new Aluminum bottom!all for under a hundred bucks.

Tried to prefab as much as I could in the garage stringers,bulkheads,motor mounts etc.

Starboard stringer bedded in peanut butter. I used epoxy to join splices.