Re: The R?surrection of the SeaGem

Hey EZ,

Thats how I built the boat

me and Johnny Cash have a lot in common ( One piece at a time) The only difference is I was sneaking the parts in LOL

Hey Vegas,

We put an auto q-jet on her just to run it on muffs. She ran like a champ. Could not get the marine one tuned she is sucking way to much air. The RPM drop was a float adjustment.

With having the auto q-jet on her I was able to perform some tests. Vacuum at WOT was off the chart , the q-jets are way too small. I am defiantly going to put a 750 on her and hope to get it down to -1 to-1.5hg

I been working my wife for a few days over the parts now. Friday I told her I was going fishing Saturday. When she woke up and I was still home she asked why I wasn't out on the water. I hung my head in sadness

and said " the carb is messed up and could ruin the engine from running too lean, all my hard work would be down the drain" . THEN I said the worst part about it is the season is almost over not to mention I really wanted to take the kids fishing for my birthday next weekend

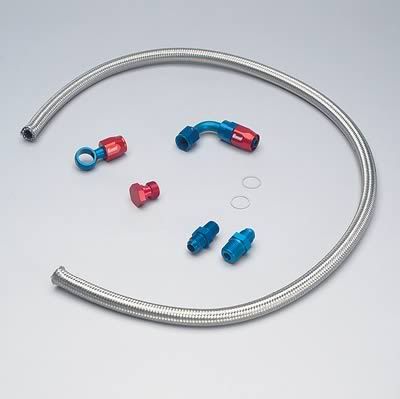

I have trimmed my list down some, If I get the rebuilt mod #9910 750, the performer eps manifold, a gasket set and an aeroquip fuel supply line for 494.75 shipped

The one thing I am unsure about is the aeroquip fuel line, whether or not its USCG legal.

Summit Link to fuel line

Anybody know if I can use this???

And I quote from boatbuilder.net

Fuel Hose: When fuel hose is used it must be either USCG Type A1, USCG Type A2, USCG Type B1 or USCG type B2. Where you use it determines what type you use.

From the fuel inlet on the engine (usually the fuel pump) to the carburetor you must use Type A1 or A2.

Each fuel vent line or fill line must be USCG Type A1 or A2 and the line from the fuel tank to the engine inlet must be type A1 or A2;

The US EPA has changed this too. Fuel hose must now meet much stricter standards for evaporative emissions. Look for hose labeled USCG Type A1-15, USCG Type A2-15, USCG Type B1-15 or USCG type B2-15. This means it meets the new EPA standard.

UNLESS:

if no more than five ounces of fuel is discharged in 2 1/2 minutes when:

(A) The hose is severed at the point where maximum drainage of fuel would occur,

(B) The boat is in its static floating position, and

(C) The fuel system is filled to the capacity market on the tank label.

Then you may use Type B1 or B2.

As a practical matter, few boat builders want to have to stock two types of hose, so most buy only Type A1 and use it everywhere. This is fine. Just be sure that you put in your owner's manual that the hose from the fuel pump to the carburetor and the vent and fill hose must be TYPE A1 or A2.

So what is the difference between A1, A2, B1, and B2? First the difference between A and B. A type hose has to pass the 2 ? minute fire test, B does not. The theory is the A is under more pressure than B, and being on the engine is exposed to more danger of fire than B. Since B is between the pump and the tank, if a leak occurs, the pressure rapidly drops to zero and the pump just sucks air, stopping the engine. Fuel doesn't get sprayed all over the place. With Type A, since it is between the fuel pump and the carburetor, it is under pressure and there is the potential that fuel will be sprayed around.

The difference between Type 1 and 2 is the permeability. All hose allows a small amount of vapor to pass out through the wall of the hose. The more permeable the hose is, the more vapor passes through. A1 and B1 pass much less than A2 and B2. About 1/3 as much. The Coast Guard Sets the standard for the amount that is allowed.

As Of 10/10/09: The US EPA has changed the permeability requirements for fuel hose. It must now allow not more than 15 grams/square meter of vapor to escape from the hose in 24 hours. This is 1/20 of what the USCG requirement was for type A2 and about 1/7 of the A1 hose. If is a very significant change. So check with your hose supplier.

You do not have to use hose! You can use metallic lines. Some manufacturers do. For example, Mercury Marine inboard engines come with steel fuel line from the fuel pump to the carburetor. Metal lines do not allow vapor to escape through the fuel line walls.

Metallic fuel Lines: If you use metallic fuel lines, the ones that run from the fuel tank to the fuel inlet on the engine must be one of the following; seamless annealed copper, nickel-copper, or copper-nickel. From the fuel pump to the carburetor they can be any metal you want to use. Beware. You could set up a galvanic couple and the tube will be eaten away like powder. Choose carefully if you use metal fuel line from the pump to the carburetor. Do not use Copper tubing.

I go similar issues...hope to adjust the float a bit and solve it...or wait for you to fix YOUR issue and duplicate the fix....

I go similar issues...hope to adjust the float a bit and solve it...or wait for you to fix YOUR issue and duplicate the fix.... Happy weeknd Billy!

Happy weeknd Billy!