Dennischaves

Chief Petty Officer

- Joined

- Nov 9, 2016

- Messages

- 439

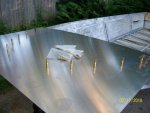

Transom looks great

I have a pair of pants that have a torn open hole in a very sensitive location from the same thing happening to me with a wire wheel.

Ooffa watch out for the jewels and belly rolls!

Well, I HAVE been trying to shed some pounds. Just not that way. :rant:

Watermann I could really use your input on the transom cap installation when you have the time please.

I decided not to use any fasteners on my SS transom caps (V5 has 3 piece caps) as I didn't want to add numerous holes into such a skinny section of the transom wood. A bead of sealer/adhesive under the cap and weight or clamp, then with a motor over the top insures your cap will never come off. If you want the finish to be perfect then fill the tiny holes and paint it before installing.

I used Marine Tex, "strong as steel, sands like wood" but I have to admit I'm a horrible body and fender man. The MT sticks to AL very well and sands great unlike JB weld and auto body filler is a bad idea on boats as some might suggest using it, it's porous and will absorb water if exposed.