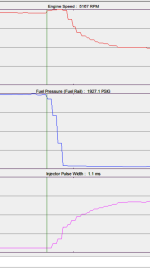

I can only see two inputs to the ECM that act weird. MAP and fuel pressure.

It was a toss up as which I would recommend first. My call was the MAP, because of the "gold rule" when a tech is guessing --- Pick the cheapest and easiest first.

I think it's now time to replace the fuel pressure sensor.

After

@Lpgc comments, I went back and looked at all the ECM outputs. The ones that start changing all have a lag behind the MAP and FP. I have good confidence in Diacom's ability to output data in real time.

While this still could be a lack of or aerated fuel (is there a flexible fuel line between the low pressure pumps and the HPFP?) you are measuring low pressure right at the pump, so if there is a restriction. It wouldn't show up on the gauge.

But fuel pressure is working just like it should until RPMs get to high. It's able to reach full pressure and maintain it for a long time, it's just once RPMs get to high.

It would be nice if Diacom would monitor PWM to the HPFP. Maybe give them a call to ask? Or have you looked at all the possible monitors to see if it's included in any of the data sets?