InMotion

Commander

- Joined

- Nov 3, 2011

- Messages

- 2,080

Re: 1960's Falcon Rebuild (New Title)

Hey Fellas.... ok I could use some help here.... This is a couple of weeks in advance, but I have a couple of ideas how to do this but would love some other ideas/thoughts. So please weigh in with your thoughts.

Premise:

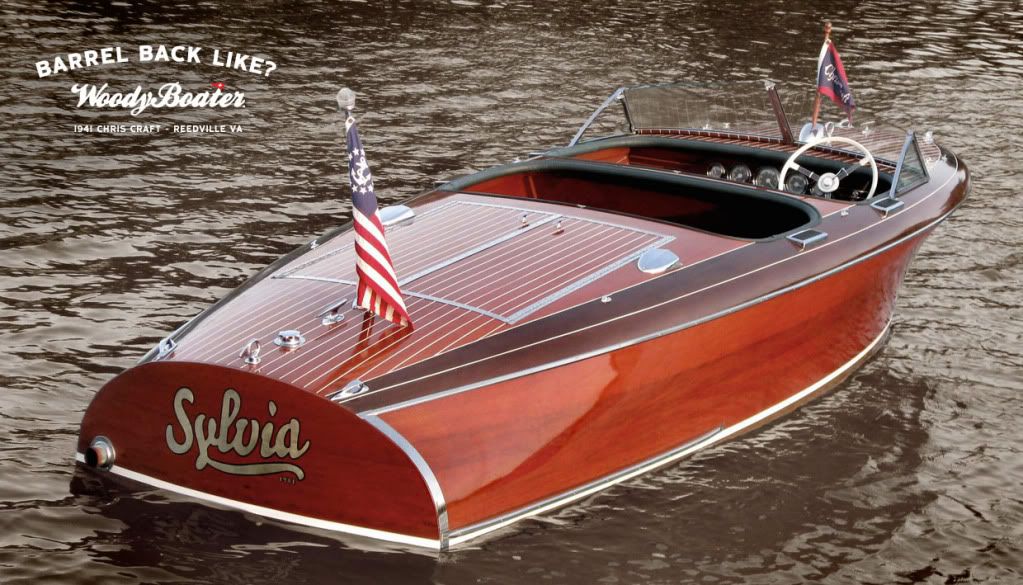

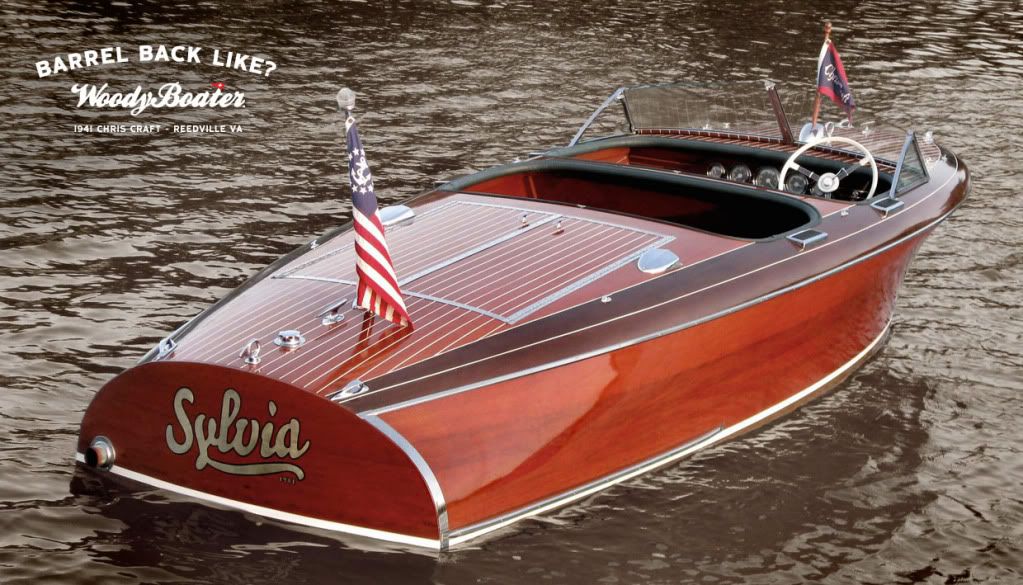

This is what I am doing to the stern of the boat....

Basically, creating a half moon curve --- like a barrelback boat would have. I will have a jack plate for the motor to hang off of. No splashwell as the back 3 feet of the boat or so will be cedar strip.

Issue is that the existing transom metal is a typical outboard setup with the usual U shaped transom.... so my thoughts are:

Option 1:

Cover the transom with cedar to above the water line from edge to edge of the transom. I will have to put some kind of spacer in above the metal to fill the gap above the top of the existing transom top.

The cedar will be coated in 6+ coats of spar to protect it.

Option 2:

Same as Option 1 but use plywood as a backer and cover it laterally with cedar strips and use cedar to strips cut for the bottom and side edges to hide the plywood. Again coat it with 6+ coats of spar to seal it up. Also, again it will be fairly far down the back of the transom, but above the water line. It will no doubt get wet with waves, etc.

Option 3:

Same as 1 but only come down enough to cover the top of the transom --- so total of maybe 4-6 inches from the top of the curve to the bottom of the wood. Nice part is that it will likely stay dry for the most part. Polish the transom and fill in the multitude of holes (like splashwell drain holes) which may not look to good. I could extend it to that level... but would likely have to use option 2 plywood/cedar option to get the wood width necessary to cover that far down.

Option 4:

Suggestions....

That's the issue guys... I've pretty much got the rest worked out to turn this into a wooden boat on top and polished aluminum boat from the gunwales down... but the back is a bit tricky....

Suggestions welcomed...

Thanks fellas!

Jim

Hey Fellas.... ok I could use some help here.... This is a couple of weeks in advance, but I have a couple of ideas how to do this but would love some other ideas/thoughts. So please weigh in with your thoughts.

Premise:

This is what I am doing to the stern of the boat....

Basically, creating a half moon curve --- like a barrelback boat would have. I will have a jack plate for the motor to hang off of. No splashwell as the back 3 feet of the boat or so will be cedar strip.

Issue is that the existing transom metal is a typical outboard setup with the usual U shaped transom.... so my thoughts are:

Option 1:

Cover the transom with cedar to above the water line from edge to edge of the transom. I will have to put some kind of spacer in above the metal to fill the gap above the top of the existing transom top.

The cedar will be coated in 6+ coats of spar to protect it.

Option 2:

Same as Option 1 but use plywood as a backer and cover it laterally with cedar strips and use cedar to strips cut for the bottom and side edges to hide the plywood. Again coat it with 6+ coats of spar to seal it up. Also, again it will be fairly far down the back of the transom, but above the water line. It will no doubt get wet with waves, etc.

Option 3:

Same as 1 but only come down enough to cover the top of the transom --- so total of maybe 4-6 inches from the top of the curve to the bottom of the wood. Nice part is that it will likely stay dry for the most part. Polish the transom and fill in the multitude of holes (like splashwell drain holes) which may not look to good. I could extend it to that level... but would likely have to use option 2 plywood/cedar option to get the wood width necessary to cover that far down.

Option 4:

Suggestions....

That's the issue guys... I've pretty much got the rest worked out to turn this into a wooden boat on top and polished aluminum boat from the gunwales down... but the back is a bit tricky....

Suggestions welcomed...

Thanks fellas!

Jim

Last edited: