Re: 1979 Champion Bass Boat - Tear Down and Restoration -- with PICS

Clamping the Plywood

What you use to clamp the plywood isn't so important, as long as the plywood is flat and the clamping pressure is fairly even. As you'll see, I invested in a highly expensive clamping system, to ensure that it was properly clamped.

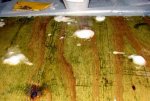

The instructions on the adhesive said that for wood, apply the adhesive to only one side. So once I had the glue spread on one piece, I flipped it over, lined up the edges, and set them together.

As I predicted, the two boards did not mate up in the center because of the slight warp they had developed.

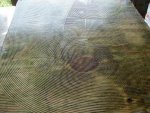

Here I have placed the plywood/glue sandwich on my clamp's base, which is perfectly flat and will not bend under pressure.

Now I apply the pressure plate to the plywood, centering it. The pressure plate is cast steel, in 1/4" X 1-1/2" segments. It will force the plywood perfectly flat when pressure is applied, without any deformation.

Finally, the clamp mechanism is used to apply approximately 1200 pounds of clamping force. It's quite an expensive clamp system, but it has many other uses, so I think it was worth the price.

The adhesive instructions say to keep the pieces clamped for 24 hours. I will likely leave it for 48 hours, just to be sure.

Clamping the Plywood

What you use to clamp the plywood isn't so important, as long as the plywood is flat and the clamping pressure is fairly even. As you'll see, I invested in a highly expensive clamping system, to ensure that it was properly clamped.

The instructions on the adhesive said that for wood, apply the adhesive to only one side. So once I had the glue spread on one piece, I flipped it over, lined up the edges, and set them together.

As I predicted, the two boards did not mate up in the center because of the slight warp they had developed.

Here I have placed the plywood/glue sandwich on my clamp's base, which is perfectly flat and will not bend under pressure.

Now I apply the pressure plate to the plywood, centering it. The pressure plate is cast steel, in 1/4" X 1-1/2" segments. It will force the plywood perfectly flat when pressure is applied, without any deformation.

Finally, the clamp mechanism is used to apply approximately 1200 pounds of clamping force. It's quite an expensive clamp system, but it has many other uses, so I think it was worth the price.

The adhesive instructions say to keep the pieces clamped for 24 hours. I will likely leave it for 48 hours, just to be sure.

Last edited: